轧机扭线导向装置简介

Release time: 2025-05-22

In the world of metalworking and steel production, efficiency, precision and safety are of paramount importance. Twist guides are a key component in ensuring smooth operation of rolling mills. It plays an important role in ensuring seamless production of high-quality metal products.

What are Twist Guides?

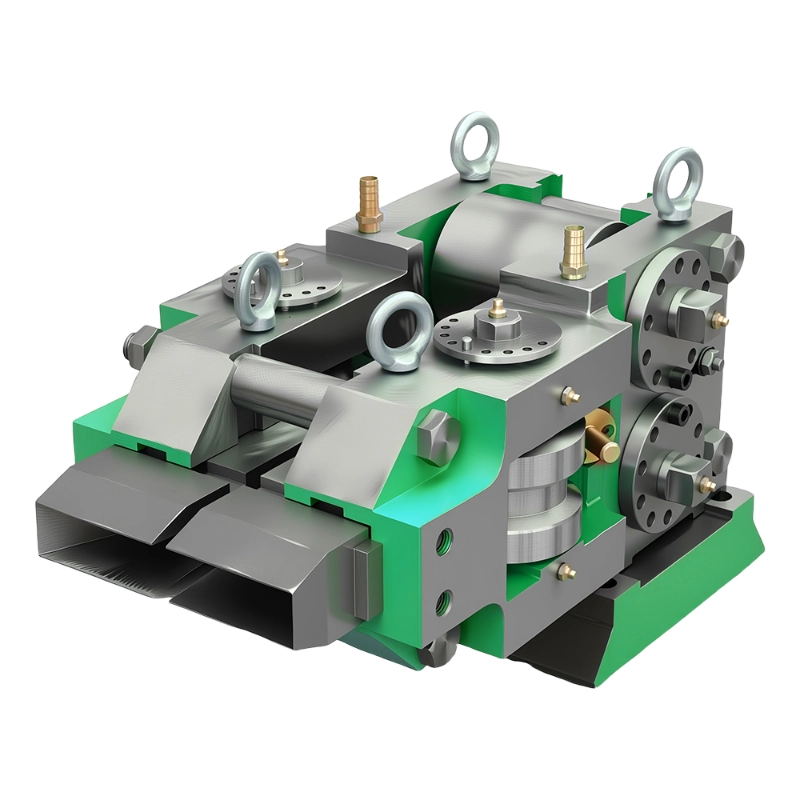

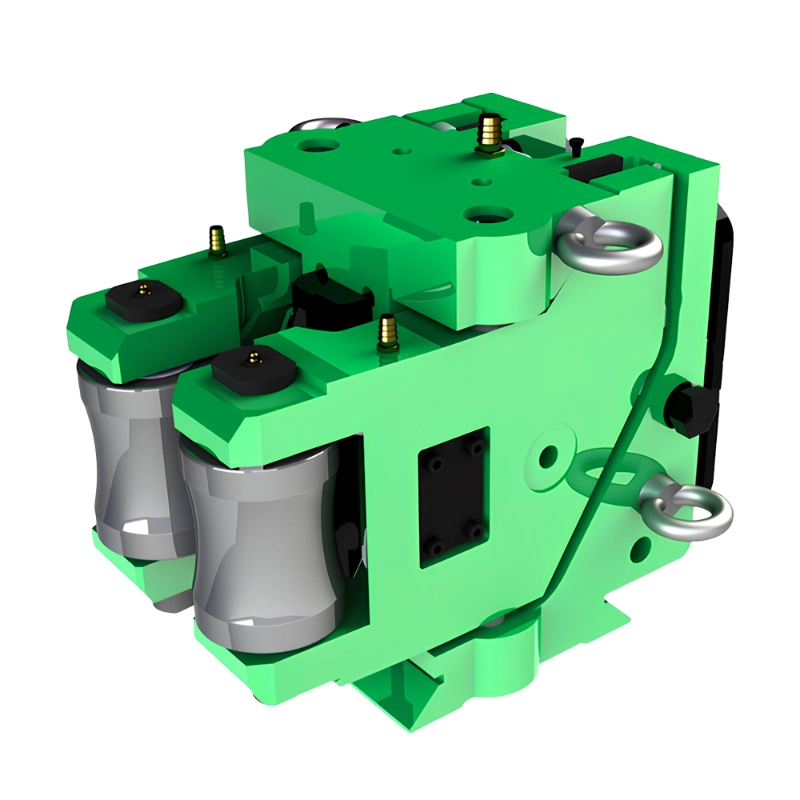

A twist guide is a device used in rolling mills to control the direction of metal as it passes through the various rollers. Its main function is to maintain the correct angle of the metal strip or bar during the rolling process, preventing it from twisting or misaligning. This ensures that the final product is straight and uniform, which is essential for further processing or end-use applications.

Twist guide are typically installed in rolling mill lines, either before or after the rolling mill stands, and are adjustable to accommodate different material types and thicknesses. They are often used in conjunction with other equipment, such as tension systems and roller guides, to maintain optimal control over the path of the metal.

Why are twist guides so Important?

Improved Product Quality: Twist guides help prevent torsion in metal strips or bars, which can cause defects such as uneven thickness, warping or uneven surfaces. By providing constant control over the material, manufacturers can ensure that the final product is dimensionally accurate and of the highest quality.

Improved Efficiency: By ensuring that the metal moves through the mill in a straight line, the twist guide reduces the likelihood of material jams, interruptions, or the need for corrective action. This improves the overall productivity of the mill, resulting in shorter production cycles.

Reduced Material Waste: The twist guide minimizes the chance of metal being misaligned during the rolling process, which can result in significant material waste. This is particularly important in industries where material costs are high, as minimizing waste directly translates into reduced production costs.

Improved Safety: Misaligned or twisted metal strips can damage mill equipment and even pose a safety risk to operators. Twist guides help keep the material properly aligned, reducing the likelihood of accidents or equipment failures.

How do Twist Guides Work?

The working principle of a twist guide is its ability to change the direction of a metal strip or bar as it moves through the mill. This is typically achieved by using a set of adjustable rollers that apply force to the metal, causing it to rotate or adjust its angle. By controlling twist and alignment, the twist guide ensures that the metal moves along a smooth path, minimizing the risk of misalignment or twisting.

Most twist guides are equipped with advanced sensors or monitoring systems to track the position of the metal and adjust the twist accordingly. This provides a real-time solution to prevent misalignment, ensuring the mill is running at peak performance.

Choosing the Right Twist Guide for Your Mill

When choosing a twist guide for your mill, there are several factors to consider:

Material Compatibility: Different materials have different properties, so it is critical to choose a twist guide that can handle a specific metal. Whether it is steel, aluminum, or copper, the design of the twist guide should accommodate the characteristics of the material.

Size and Adjustability: The size of the twist guide should match the size of the mill and the type of metal being processed. Also, choose an adjustable guide that can handle a variety of metal thicknesses and shapes.

Durability and Maintenance: Twist guides are subject to constant stress and wear during the rolling process, so it is critical to choose a guide that is durable and easy to maintain. High-quality materials and a design that minimizes wear will ensure the life of the twist guide and reduce maintenance downtime.

Automation and monitoring features: Modern twist guides are equipped with automation features such as sensors and control systems that help maintain optimal alignment throughout the rolling process. These features improve mill efficiency and provide real-time data for better decision making.

Conclusion

Twist guides are a small but critical component of the mill process and play an important role in improving the quality, efficiency and safety of metal production. By preventing twisting and misalignment, twist guides ensure that metal products are produced to precise specifications with minimal waste.

So when choosing a twist guide, consider factors such as material compatibility, adjustability, durability and automation. With the right twist guide, your mill will run more efficiently, thereby improving product quality and reducing production costs.