轧机导轨类型介绍

Release time: 2025-05-26

In the working environment of the rolling mill, the guides, as the key components connecting various parts, play an important role. Different types of rolling mill guide can not only optimize the operating efficiency of the rolling mill, but also provide more precise control according to production needs. We will introduce some types of rolling mill guide produced by Shennuo Metallurgical to help you understand their respective characteristics and advantages and improve the safety and production efficiency in the production process.

Sliding guide

Sliding guide are a traditional type of guide that are widely used in the infrastructure of rolling mills. Its main feature is that it relies on friction to achieve sliding, so regular lubrication is required to reduce friction and extend service life. The installation and maintenance of sliding guide are relatively simple and low-cost, so they are widely used in many early-construction rolling mills. However, due to the large friction, it may face performance degradation during high-load and high-speed production processes.

Twist guide

The twist guide rail has a unique design, which effectively eliminates the adverse effects of friction through a twist structure. It is usually used in rolling mills that need to withstand high torque and large loads. Compared with traditional sliding guides, twist guides can provide higher stability and lower friction, thereby improving work efficiency, and reducing energy consumption and wear. It is suitable for some complex rolling processes, especially in high-speed rolling, to ensure the smooth operation of the equipment.

Rolling guides

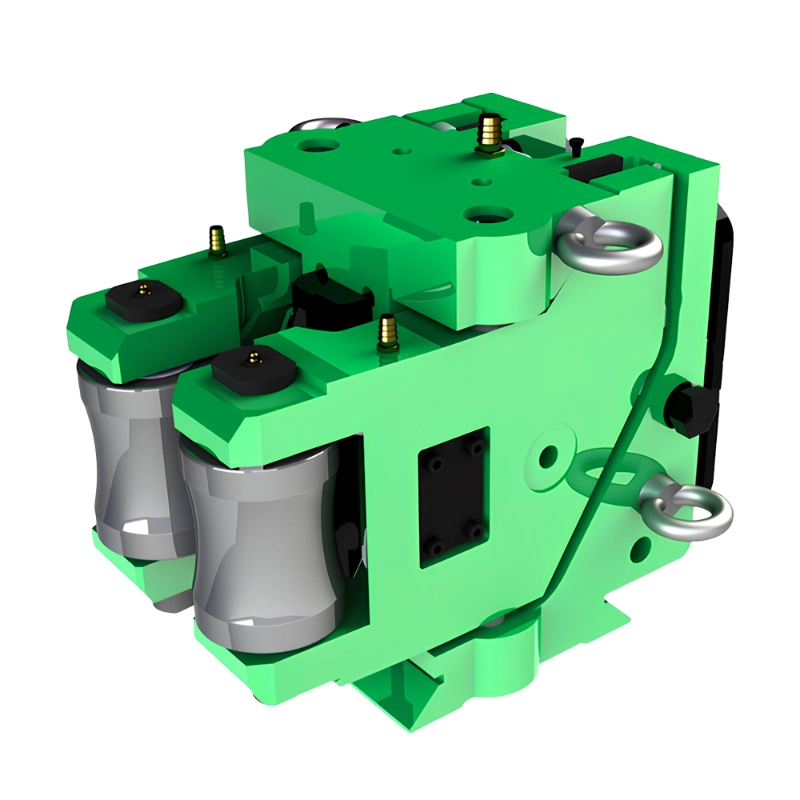

The core of rolling guides is to use rolling elements (such as balls or rollers) to achieve motion transmission. Its biggest advantage is that it has low friction, which can reduce energy waste and improve the operating efficiency of the production line. In addition, rolling guides are suitable for high-speed and high-precision occasions, and can provide smoother and more precise motion control. Although the price of rolling guides is relatively high, its performance advantages are very worthwhile in the long run.

分割指南

Splitting guides are mainly used in the splitting process of rolling mills. It is specially designed to ensure the accuracy and effect of splitting when cutting steel plates or metal materials. This guide can effectively reduce the error of materials during the slitting process, ensuring that the products produced are consistent in size and smooth in surface. Therefore, high-precision splitting guides are particularly important in production, especially when producing high-quality steel, splitting guides are indispensable key components.

Sizing guides

The function of sizing guide is to ensure the fixed length of steel or other metal materials processed by the rolling mill. By controlling the length of the material, sizing guides can not only improve production efficiency, but also reduce the generation of waste and reduce production costs. Sizing guides are usually combined with automatic control systems to achieve high-precision length control and are widely used in small and medium-sized rolling mills and precision rolling processes.

型钢导轨

Section steel guides are a type of guide made of steel material with high strength and stability. It is usually used in rolling mills with large loads and is suitable for use in heavy-load working environments. Section steel guides can effectively withstand the huge pressure generated during the rolling process and ensure the smooth operation of the rolling mill. Due to its high durability, section steel guides are suitable for long-term equipment and can reduce the cost of frequent replacement.

Conclusion

Different types of rolling mill guides play their own unique roles in different application scenarios. Whether it is a traditional sliding guide or a high-precision rolling guide, each guide has its unique advantages and scope of application. When choosing a suitable guide, you need to consider multiple factors such as the specific requirements of production, load size, working environment, and maintenance cost. With the continuous development of technology, rolling mill guide technology will become more advanced, which can not only improve production efficiency, but also ensure more stable and precise operation.

By understanding these types of guides, you can choose the most suitable type of guide according to your needs, providing strong support for the efficient operation of the rolling mill. At the same time, you are welcome to consult Shennuo Metallurgical about any questions about rolling mill guides. As a manufacturer specializing in the production of rolling mill guides, we will provide you with the best service.