5 Critical Tips to Extend the Service Life of Your Entry and Exit Mill Guides

Release time: 2025-12-26

İçindekiler

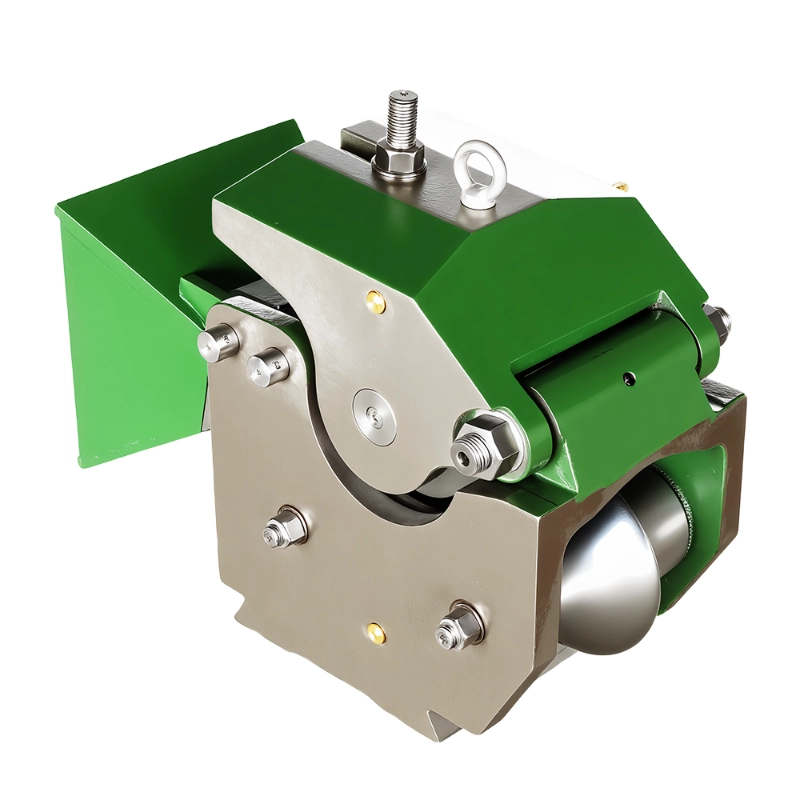

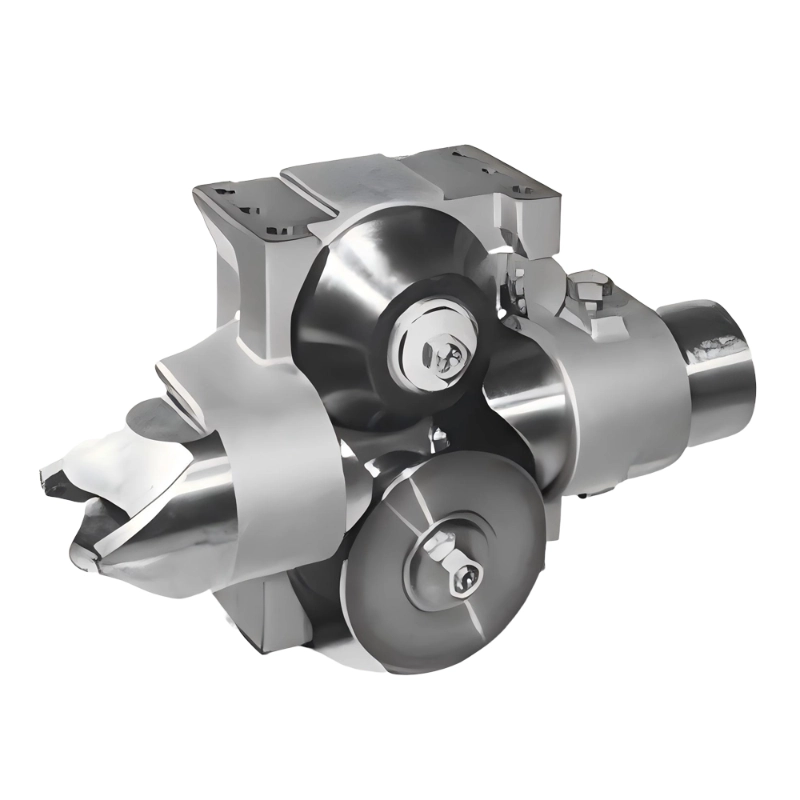

In the high-pressure environment of a rolling mill, entry and exit mill guides are silent workhorses. They ensure the precise positioning of the workpiece as it passes through the rolls, directly impacting both product quality and operational safety. However, because they are constant contact points, wear and tear are inevitable.

If you are looking to minimize downtime and maximize your investment, maintenance is key. Here are five critical tips to extend the service life of your mill guides while ensuring peak performance.

Prioritize High-Wear Resistant Materials

The longevity of a guide starts with its composition. Traditional guides may fail prematurely under high-speed friction. Transitioning to a wear-resistant entry and exit mill guides made from advanced alloys or treated steel can drastically reduce the rate of surface degradation. These materials are specifically engineered to withstand the thermal shock and mechanical abrasion inherent in hot rolling processes.

Ensure Precise Alignment and Installation

Even the best equipment will fail if it is misaligned. Utilizing a high-precision entry and exit mill guides ensures that the steel bar or wire rod enters the roll pass at the exact required angle. Misalignment causes uneven wear on one side of the guide and can lead to “cobbles” or surface scratches on the finished product. Regular calibration of the guide holder and the guide box is essential to maintain this precision.

Implement Robust Lubrication and Cooling

Friction is the enemy of durability. A constant, high-pressure cooling and lubrication system is vital. Proper water cooling prevents the guide from overheating, which maintains the hardness of the material. For sliding mill guides, effective lubrication reduces the friction coefficient between the guide and the workpiece, preventing the “sticking” of metal particles that can cause premature erosion.

Opt for Customized Solutions for Specific Passes

Standardized guides don’t always fit specialized rolling requirements. Using a customized entry and exit mill guides allows you to match the guide’s internal geometry perfectly to your specific pass design. Customization ensures a tighter fit and more stable guiding, which reduces vibration. Reduced vibration means less mechanical stress on the guide components, effectively lengthening their usable life.

Establish a Proactive Inspection Routine

Don’t wait for a failure to take action. Establish a “Predictive Maintenance” schedule. Inspect the contact surfaces of your entry and exit mill guides for signs of pitting, cracking, or excessive thinning. By replacing small wear parts before they cause a total system failure, you protect the entire rolling line’s integrity and avoid costly emergency shutdowns.

Çözüm

Extending the service life of your rolling mill consumables is a combination of choosing the right hardware and maintaining strict operational standards. By investing in a high-precision entry and exit mill guides and focusing on wear-resistant technologies, you not only save on replacement costs but also improve the overall yield of your mill.

As a professional manufacturer, Shennuo specializes in providing high-performance solutions for the metallurgical industry. Our range of customized sliding mill guides is designed to meet the most rigorous industrial standards, ensuring your production line stays moving longer.