The Role and Technical Requirements of Rolling Mill Entrance Guides

Release time: 2025-09-13

Table of Contents

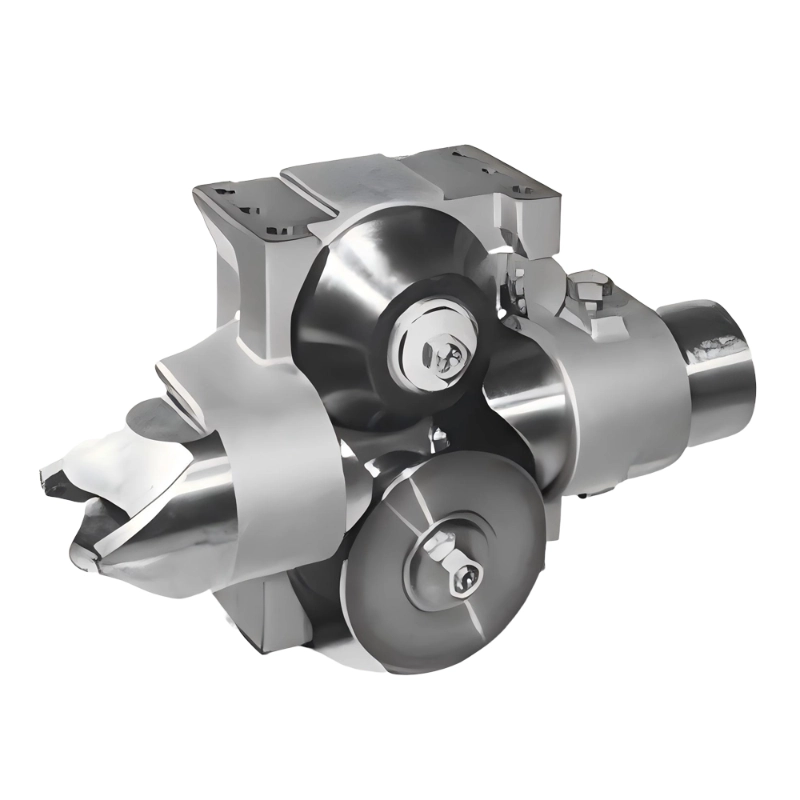

In modern steel production, rolling mills are critical production equipment, and their performance directly impacts production efficiency and product quality. As an integral part of rolling mill operations, rolling mill entrance guides play a crucial role. They not only ensure the smooth entry of billets or other metal materials into the rolling zone, but also improve rolling stability, reducing production process failures and material waste. So, what exactly do rolling mill entrance guides do? What are their technical requirements? Let’s explore these details.

The Role of Rolling Mill Entrance Guides

The primary function of rolling mill entrance guides is to guide billets or other metal materials entering the rolling mill, ensuring they stay on track. Specifically, guides can:

Improve material passing accuracy: At the rolling mill entrance, the surface condition and position of the billets must be extremely precise. Guides prevent the billets from shifting during entry, ensuring their precise positioning.

Ensuring Rolling Stability: If the billet deflects or becomes unstable upon entering the rolling mill, it can affect the subsequent rolling process, resulting in an uneven surface and even causing production line downtime. The role of the guide is to ensure that the material remains stable upon entering the rolling mill, thereby improving rolling efficiency.

Reducing Waste and Failure: If the guide is poorly designed or malfunctions, the billet may become stuck or misaligned, which not only wastes raw materials but can also damage equipment and affect production efficiency. An efficient rolling mill entry guide can effectively reduce these issues.

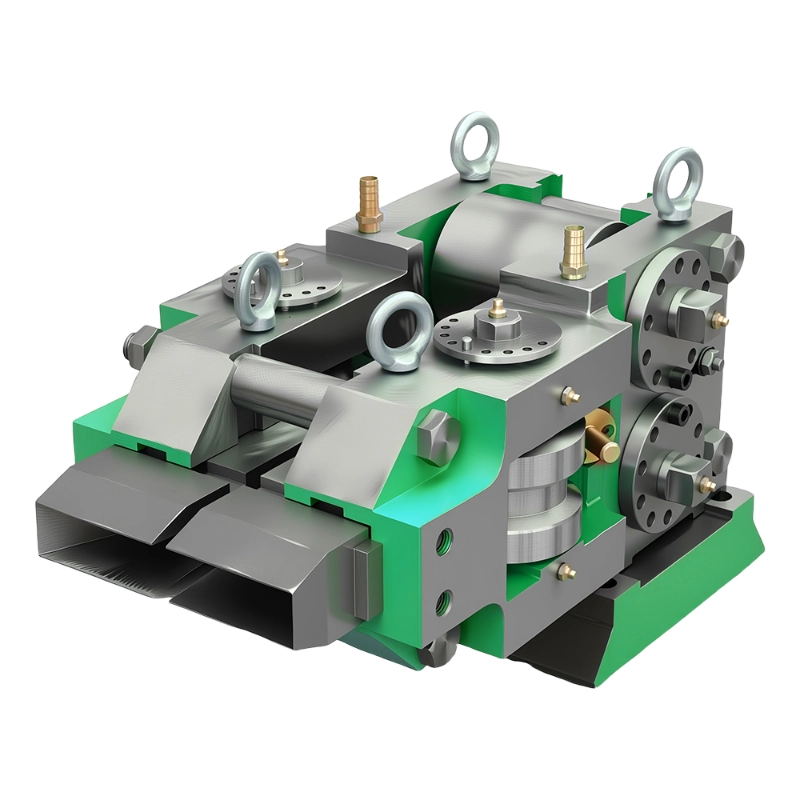

Technical Requirements for Mill Entrance Guides

To ensure that guides can effectively perform these functions, they must meet certain technical requirements. The following are some key technical requirements:

High-Temperature Resistance: The operating temperature of the rolling mill is extremely high, especially when the billet enters the mill, which often exceeds 1000°C. Therefore, the guide material must have excellent high-temperature resistance to prevent deformation or damage under such high temperatures.

Wear Resistance: The contact between the rolling mill entry guide and the billet is frequent and intense, so the mill entry guide must possess strong wear resistance. This not only extends the service life of the mill entry guide but also reduces wear-related failures and downtime.

High strength and high load-bearing capacity: Because rolling mills often face high loads during operation, rolling mill entry guides must possess sufficient strength to support these loads and prevent deformation or fracture during operation.

Design accuracy: The design of rolling mill entry guides requires precision, and dimensional errors must be kept within a minimum. Inaccurate dimensions can prevent the smooth passage of billets, and may even cause them to become stuck or deflect. To ensure optimal performance, rolling mill entry guides require extremely high design accuracy.

Thermal fatigue resistance: Because rolling mills operate in high temperatures and frequently fluctuating operating conditions, rolling mill entry guides must exhibit strong thermal fatigue resistance. This ensures stable operation under long-term, high-temperature, and high-load conditions.

How to meet these technical requirements?

To ensure that mill entry guides meet these technical requirements, rolling mill entry guide manufacturers typically use high-performance alloy steels, ceramics, or other specialized materials. Furthermore, factors such as the guide’s geometry, surface treatment, and dimensions must also be considered during design. For example, sophisticated computer simulation techniques are used to optimize the guide’s design to ensure stable operation in high-temperature, high-load environments.

Furthermore, with the development of intelligent technology, advanced monitoring systems have been introduced to manage the operation of rolling mill entry guides. Sensors monitor the rolling mill entry guide’s operating status in real time and automatically adjust its position and angle, further improving its efficiency and stability.

Conclusion

As a crucial component of the rolling process, rolling mill entry guides serve more than just simple guidance. Their performance is directly related to the quality, efficiency, and safe operation of steel production. To meet the demands of modern rolling mills for efficient and stable production, high-quality rolling mill entry guides must exhibit superior performance in multiple areas, including high temperature resistance, wear resistance, and strength. With technological advancements, the design and materials of mill entry guides are constantly being innovated and upgraded. Rolling mill entry guides will become more intelligent and energy-efficient, driving the steel industry towards greater efficiency and environmental friendliness.