The Importance of Roller Guides in Rolling Mills

Release time: 2025-06-26

In the manufacturing industry, rolling mills play a vital role in the production of a wide range of metal products. These rolling mills form metal using one or more pairs of rollers. The efficiency and precision of a rolling mill largely depends on the role of rolling guides, which are an integral component to ensure smooth and precise operation.

What are rolling guides?

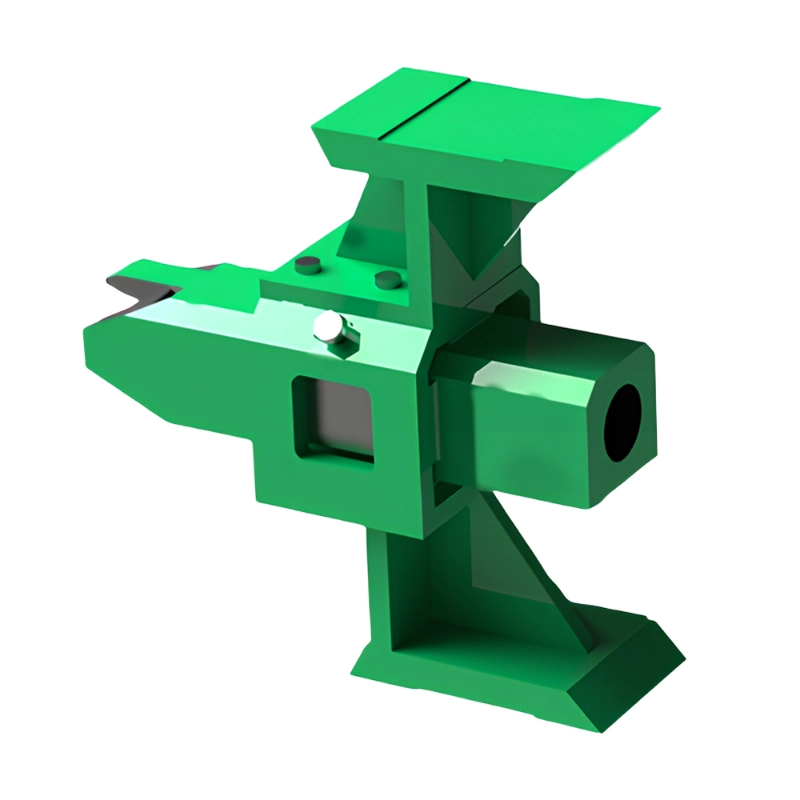

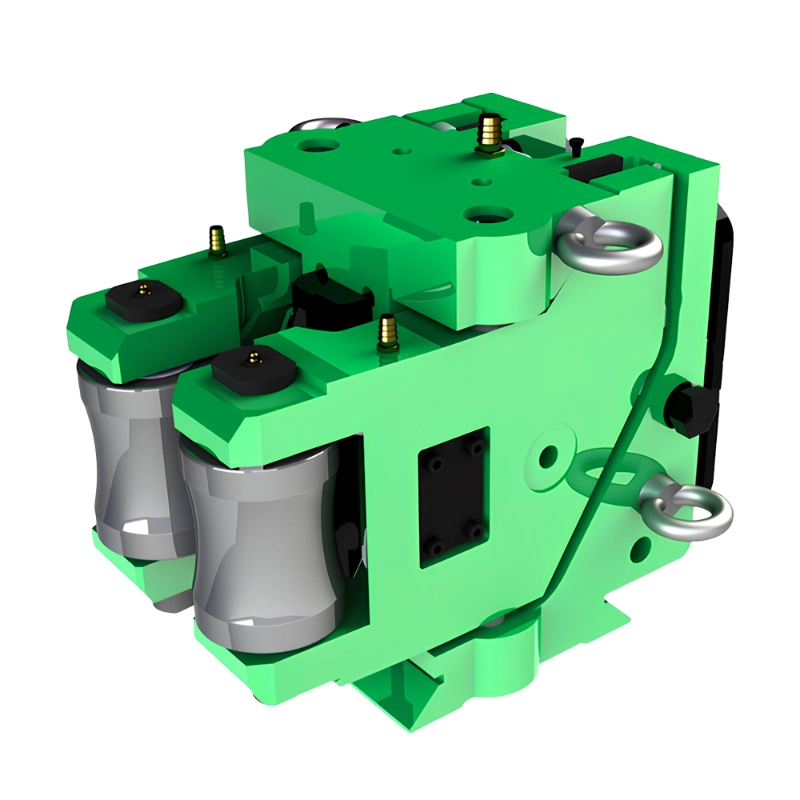

Rolling guides are mechanical devices used to guide and support metal as it passes through the rolls of a rolling mill. These guides help maintain the proper alignment of the metal, ensuring it enters the rolls at the correct angle and with the proper tension. High precision rolling guides are usually installed in front of and behind the rolls to guide the metal in a controlled manner, prevent unnecessary wear on the rolls, and improve the overall efficiency of the rolling process.

Role of Rolling Guides in Rolling Mills

Improving Precision and Accuracy: One of the most important functions of rolling guides is to ensure that the metal passes through the rolls in a precise manner. Any misalignment or inconsistency in the flow of metal can lead to defects such as uneven thickness, surface cracks, or dimensional inaccuracies. By maintaining a steady and consistent flow, rolling guides help produce high-quality metal products.

Reduced Roller Wear: Rolling guides help maintain consistent pressure and reduce friction between the metal and the rolls. This not only ensures smoother operation, but also reduces the likelihood of excessive wear on the rolls, which can prevent expensive maintenance and replacement. This will reduce the operating costs of the mill in the long run.

Minimize Downtime: Downtime is a significant concern in any industrial production, but especially in rolling mills where continuous production is critical. Rolling guides help minimize downtime by preventing problems such as metal misalignment, jamming, or roll damage. By ensuring smooth operation, these guides reduce the likelihood of production interruptions, allowing for more efficient, uninterrupted production.

Improved Operational Efficiency: Efficient operations are critical to the success of any manufacturing plant. Rolling guides help improve efficiency, allowing the mill to run at optimal speeds while maintaining consistent quality. With efficient rolling guides, operators can achieve faster processing times, higher yields, and better overall product quality.

Customized for Specific Needs: Different types of metals and rolling processes may require different types of rolling guides. For example, hot and cold rolling mills may require specialized guides that can withstand higher temperatures or different materials. Modern rolling guides are designed with flexibility in mind and can be customized to the specific requirements of the rolling mill and the materials being processed.

Why Invest in Quality Rolling Guides?

Investing in quality rolling guides is essential to ensure the longevity and efficiency of your rolling mill. Poor quality rolling guides can lead to inefficient operations, increased maintenance costs, and product defects. On the other hand, high-quality rolling guides help to better align, reduce wear, and improve overall performance.

In addition, with the metal industry’s growing demand for precision and high-quality products, it is more important than ever to ensure that every part of the rolling mill is in optimal condition. Roller guides may be just a small part of the rolling mill, but their impact on the overall operation is significant.

Conclusion

In summary, rolling guides are an important part of the rolling mill process, which provides benefits such as improved precision, reduced wear, minimized downtime, and increased operational efficiency. By investing in durable rolling guides equipment, manufacturers can ensure that their rolling mills perform at their best and produce high-quality metal products that meet market demands. Whether you are working with a hot or cold rolling mill, choosing the right rolling guides is critical to long-term success in the industry.

Hefei Shennuo Metallurgical Machinery is a leading enterprise focusing on mid-to-high-end rolling mill guides, including high-speed wire roling & sliding guides, guide beams, section & bar roling guides, bar & wire spliting guides, sizing guides, loopers, water cooling devices. If you are interested in our products, please feel free to consult us.