The Future of Rolling Mill Guides: How Automation Technology Can Reduce Production Costs

Release time: 2025-12-06

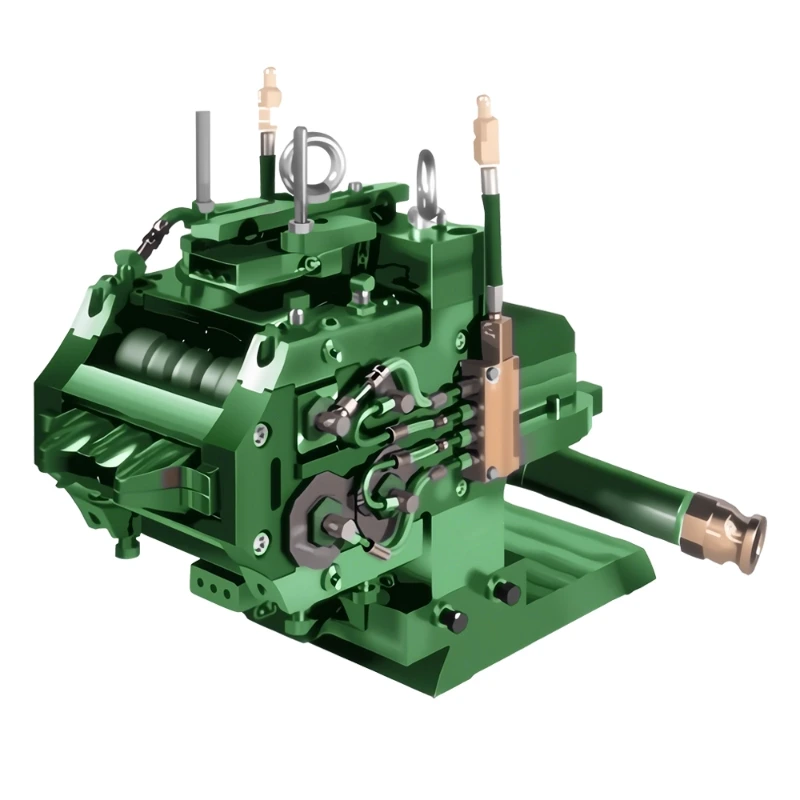

In modern steel production, rolling mill guides are critical components whose performance directly impacts product quality and production efficiency. With the development of Industry 4.0 and intelligent manufacturing, automation technology is gradually becoming an important means of reducing production costs and improving efficiency. This article will explore the application of automation in rolling mill guides and its impact on enterprise cost optimization.

Firstly, automation technology can significantly improve the production efficiency of rolling mill guides. In traditional production models, the operation of rolling mill guides relies on manual experience, leading to inconsistencies in operation and low efficiency. By introducing intelligent control systems, the operation of rolling mill guides can be automatically adjusted, ensuring that the steel remains in the optimal position during the rolling process, thereby reducing material waste and increasing output. At the same time, the automated system can also monitor the status of the rolling mill guides in real time, providing early warnings of wear or malfunctions, reducing the risk of unexpected downtime.

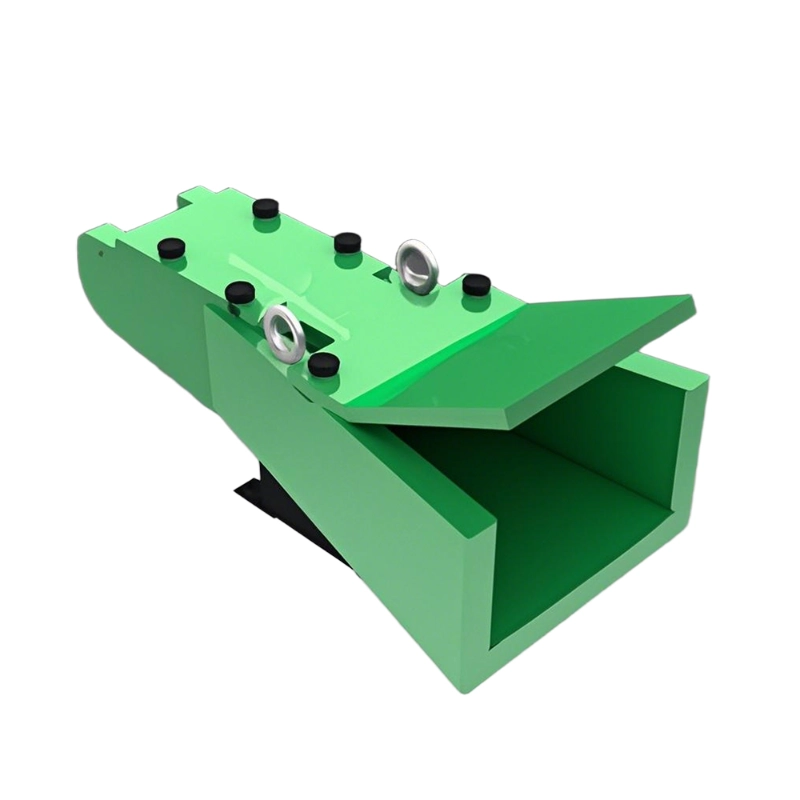

Secondly, automation technology helps extend the service life of durable rolling mill guides. Through precise pressure control and intelligent lubrication systems, the wear on the guides during operation is significantly reduced. This not only reduces maintenance costs but also reduces downtime caused by guide replacement, further lowering production costs. For large steel mills, investing in durable rolling mill guides combined with automation technology is a key strategy for achieving long-term cost control.

Furthermore, automation also promotes the intelligent upgrading of rolling mill guide factories. Modern rolling mill guide factories, through digital production management systems, can achieve full-process monitoring from raw material procurement and processing to shipment. This integrated management not only improves production transparency but also optimizes inventory management and logistics arrangements, enabling enterprises to achieve higher economic benefits while ensuring product quality.

In terms of procurement, companies are increasingly focusing on the rolling mill guides price. Through automated production, manufacturers can reduce production costs, thereby offering more competitive prices. For steel companies, this not only reduces direct procurement costs but also increases overall profits by improving production efficiency.

Finally, the application of automation technology also promotes technological innovation in rolling mill guide products. Intelligent rolling mill guides not only support remote monitoring and data analysis but can also automatically adjust operating parameters according to different rolling processes. This highly customized technological development trend allows steel companies to maintain a competitive advantage in the fierce market competition. In summary, with the continuous advancement of automation technology, the production and use of rolling mill guides are developing towards high efficiency, intelligence, and durability. By optimizing operating procedures, extending equipment life, and reducing production costs, companies can not only enhance their competitiveness but also achieve sustainable development in the steel industry. In the future, intelligence and automation will become essential features of rolling mill guide factories, bringing more economic and technological value to the industry.