Назначение прокатных направляющих листов и их решающая роль в производстве стали

Release time: 2025-08-12

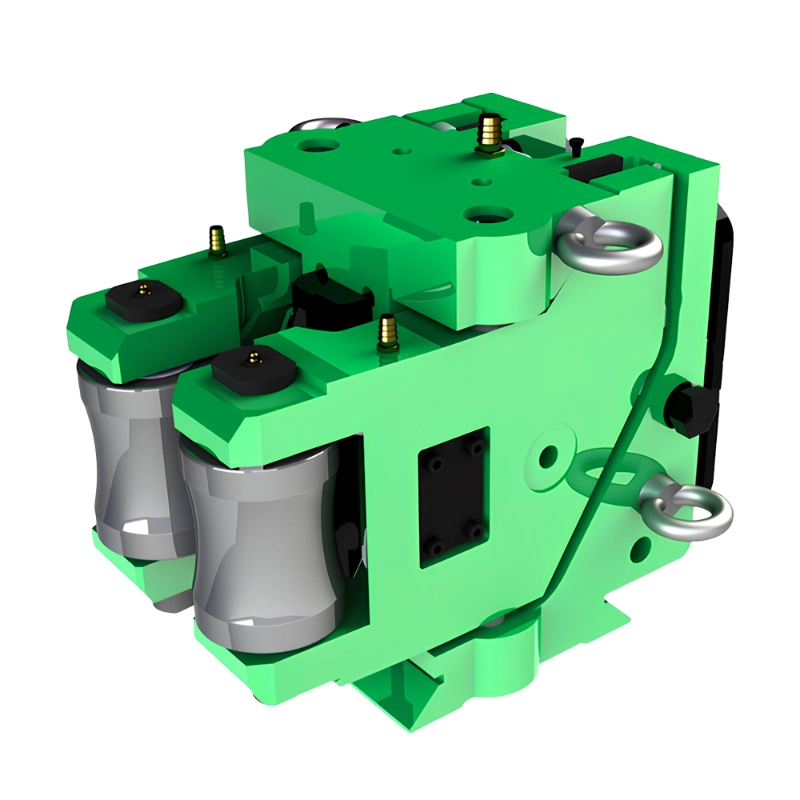

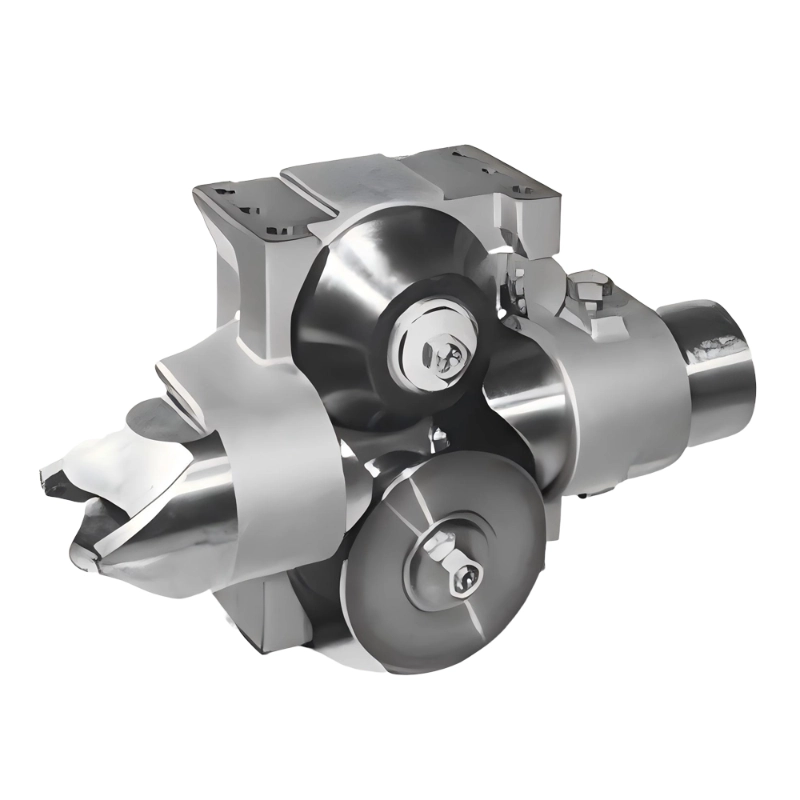

Rolling guide plates, as key consumable spare parts in bar and wire rolling equipment in the steel industry, play a vital role. They ensure smooth entry of hot rod into the wheel grooves during the rolling process, preventing winding and tail swinging, and provide both guidance and clamping. Rolling Guide plates are particularly demanding in modern high-speed wire rolling. At rolling speeds of up to 110 m/s, guide rollers (pulleys) rotate at speeds exceeding 50,000 rpm, with surface temperatures reaching 800-1100°C. They are also subject to intense physical shock and stress, making the design and material selection of guide plates crucial.

The Role of Guide Plates in the Rolling Process

Rolling guide plates play a crucial role in steel production, especially in section steel production. Their primary function is to ensure smooth entry of wire rod or bar into the wheel grooves of the next rolling process, preventing winding and tail swinging. According to industry statistics, the majority of failures in steel rolling production are related to poor guide performance. These failures not only affect production efficiency but can also lead to significant waste of resources. Therefore, selecting the right guide plate is crucial for improving production stability and extending equipment life.

In actual production, guide plates operate under extremely harsh conditions, enduring high temperatures, high speeds, and strong impacts. Under these conditions, the performance and durability of the guide plates directly impact the overall operational efficiency of the production line. If metal impurities adhere to the guide plate surface or the plate is subjected to irregular impacts, its service life will be significantly shortened. Therefore, the wear resistance and impact resistance of the guide plate are important criteria for evaluating its quality.

Advantages of Steel-Bonded Carbide Guide Plates

Traditional steel guide plates suffer from poor wear resistance and a short service life, requiring frequent replacement and increasing production costs. To overcome this problem, steel-bonded carbide high-speed wire finishing steel guide plates have been developed. These guide plates offer excellent hardness, wear resistance, thermal conductivity, and red hardness, making them particularly suitable for high-speed wire rolling processes. High-speed wire rolling can reach speeds of 80-120 m/s, placing even higher demands on the performance of guide plates.

The use of steel-bonded carbide guide plates not only improves production efficiency but also significantly reduces replacement frequency and maintenance costs. Due to their high hardness and strong wear resistance, they can operate stably in high-temperature, high-speed environments for extended periods, effectively enhancing the continuity and stability of the rolling process. In practical applications, steel mills using steel-bonded carbide guide plates have significantly improved the efficiency and reliability of their production lines, making them the preferred key component for many large steel producers.

Technical Development Trends in Guide Plates

With technological advancements, the steel industry’s requirements for rolling guide plates are becoming increasingly stringent. The development of new guide plate materials enables them to maintain excellent performance in even more extreme operating environments. For example, the use of advanced steel-bonded carbide materials not only enhances wear resistance but also significantly improves thermal conductivity and red hardness, which are particularly important for high-speed wire rolling. Furthermore, with continuous improvements in manufacturing processes, the service life of guide plates will be further extended, further improving the overall efficiency of rolling production.

Заключение

In summary, rolling guide plates play a crucial role in steel production. They not only ensure the smooth running of the rolling process but also directly impact production efficiency and equipment life. As a new, highly efficient product, high-performance steel-bonded carbide guide plates have become the preferred choice for modern steel mills. By continuously improving the performance of guide plates, the steel industry will be able to better address various production challenges, enhance overall profitability, and provide the market with higher-quality steel.