Точное управление, стабильное производство: роликовые направляющие на входе способствуют эффективному развитию сталелитейной промышленности

Release time: 2025-07-15

In the steel industry, section rolling mill, as an important production equipment, undertakes the heavy responsibility of manufacturing various steel sections. With the continuous upgrading of industrial demand, the precision and efficiency requirements of steel production are getting higher and higher. In order to ensure the smoothness of the production process and product quality, each component of the section rolling mill must be carefully designed and optimized. As an important part of it, the application of roller entry guide in section rolling mill not only plays a key role in improving production efficiency, reducing equipment loss and improving product quality, but also injects strong impetus into the sustainable development of the steel industry.

Function and role of roller entry guide

The roller entry guide is an important device for guiding steel billets in section rolling mills, usually installed at the feeding port of the rolling mill. Its main function is to ensure that the steel entering the rolling mill can pass through the entrance area smoothly and accurately, avoiding bending or dislocation of the billet due to poor guidance, thereby affecting the entire rolling process. Through the cooperation of the roller entry guide, the steel is accurately guided into the rolling area to ensure that the rolling mill works under efficient and stable conditions.

Structural features of roller entry guide

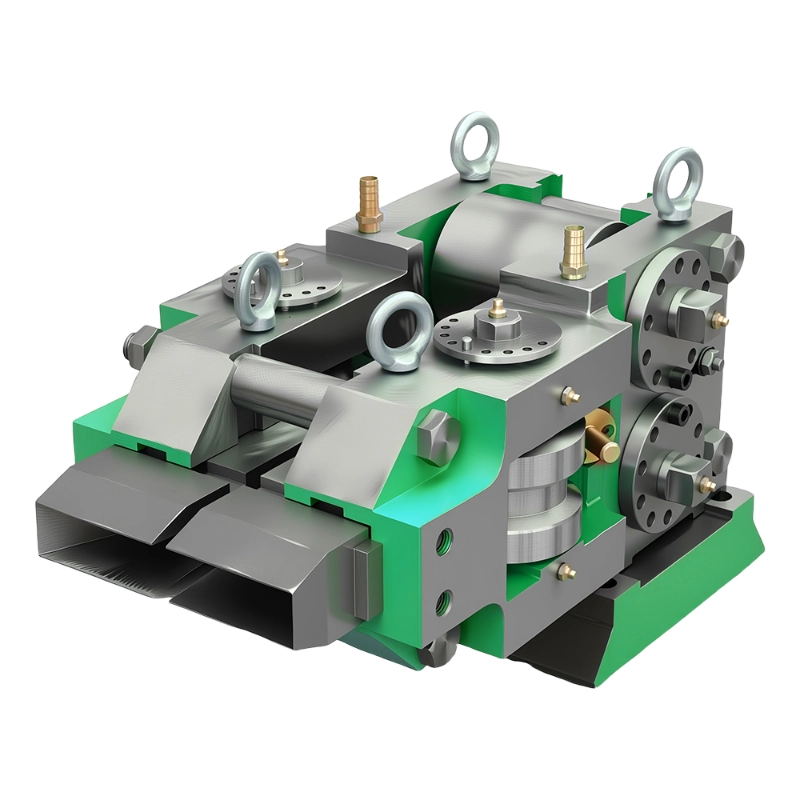

The roller entry guide is usually composed of guide, rollers and support frames. The core purpose of the guide design is to provide a smooth channel for steel to prevent the steel from deflecting or deforming when entering the rolling mill. The roller plays a supporting and guiding role by cooperating with the guide to ensure the stability and accuracy of the steel billet. The guide part is generally made of high-strength alloy steel, which has the characteristics of high temperature resistance, wear resistance and corrosion resistance, and can work stably for a long time under high temperature and high pressure environment.

Advantages of roller entry guide

Improve production efficiency

The application of roller entry guide in section steel rolling mill can effectively reduce the friction and resistance when steel enters the rolling mill. The steel can remain stable and smooth when feeding, and it is not easy to deflect or jam. This not only greatly reduces the downtime caused by adjustment, but also increases the conveying speed of steel, allowing the rolling mill to roll at a higher speed, thereby significantly improving production efficiency.

Improve product quality

The stable guidance of steel directly affects the quality of the final product. High-precision roller entry guides can effectively prevent deformation, bending or dislocation of steel when entering the rolling mill, thereby avoiding surface defects or inherent quality problems caused by uneven or deformed materials. The rolled steel is finally flatter and more uniform, and the mechanical properties and surface quality are significantly improved.

Extending the service life of equipment

During the rolling process, the friction of the steel will cause certain wear on the guide and rollers. The roller entry guide effectively reduces the friction between the steel and the equipment and reduces the wear rate of the equipment by optimizing the design and material selection. Regular maintenance and optimized roller entry guide system can extend the service life of the rolling mill, reduce production downtime caused by equipment failure, and save a lot of maintenance and replacement costs.

Energy saving and consumption reduction

The smooth operation of the roller entry guide can reduce the resistance of steel when entering the rolling mill, thereby reducing the energy consumption of the rolling mill. Since steel can pass through the guide system more efficiently, the power demand during the start-up and operation of the rolling mill is reduced, and the energy consumption is greatly reduced. The reduction in energy consumption not only helps enterprises save costs, but also conforms to the current environmental protection and sustainable development concepts advocated by the steel industry.

Maintenance and care of roller entry guides

In order to ensure the stability of roller entry guides in long-term operation, regular maintenance and care are essential. First, the wear of the guide system should be checked regularly to ensure that there is no excessive wear or deformation on the guide and roller surfaces. Secondly, the rollers need to be lubricated regularly to reduce friction and heat generation and maintain smooth operation. In addition, the guide area should be cleaned regularly to remove debris that may affect the smooth passage of steel. Finally, faulty parts should be replaced in a timely manner to avoid minor problems affecting the entire production process.

Краткое содержание

The application of roller entry guides equipment in section steel rolling mills is directly related to production efficiency, product quality, equipment service life and energy consumption. By optimizing the design and maintenance management of roller entry guides, not only can the efficiency and quality of steel production be improved, but also energy consumption and maintenance costs can be reduced. With the continuous advancement of technology in the steel industry, the innovation and improvement of roller entry guides will continue to bring higher productivity and competitiveness to steel companies and become an important force in promoting the development of the steel industry.

The roller entry guide is not just a small component in the section rolling mill. Every optimization of it means the improvement of the entire production process.