Rolling Mill Guides: Key Components to Improve Production Efficiency and Equipment Life

Release time: 2025-06-11

In modern steel production, rolling mill guides, as important mechanical components, play a vital role. It is not only related to the operating efficiency of the rolling mill, but also directly affects the production quality and the service life of the equipment. In order to better understand the role and advantages of rolling mill guides, it is necessary for us to have a deep understanding of its basic functions, application scenarios, and how to choose high-quality rolling mill guides products.

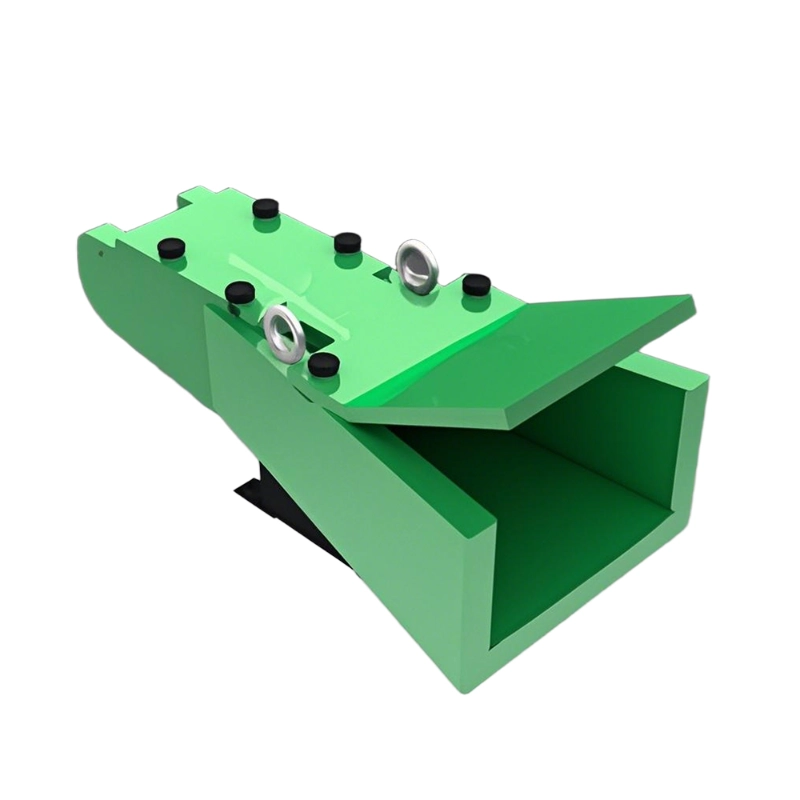

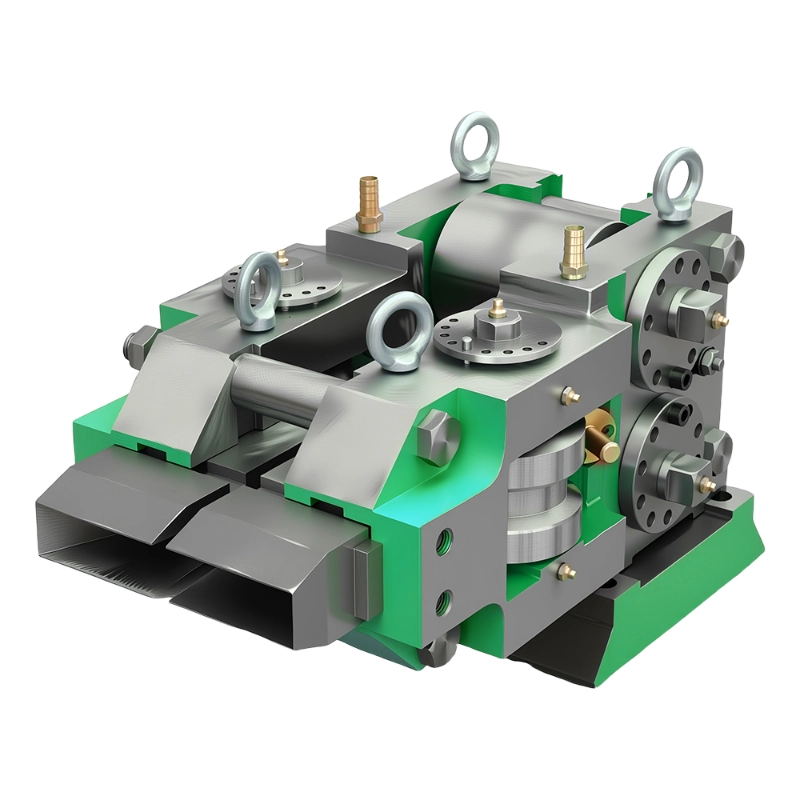

What is a rolling mill guide?

The rolling mill guide is a rail system specially designed for rolling mill equipment, which is mainly used to support and guide various transmission and conveying components of the rolling mill. It is usually made of high-strength steel, which can withstand huge mechanical loads and maintain stable operating performance. The rolling mill guide plays an important guiding role in the rolling process, ensuring the smooth operation and efficient production of the rolling mill equipment.

The main role of the rolling mill guide

Improve the stability of rolling mill operation

The rolling mill guide ensures the stable movement of the rolling mill equipment through precise track guidance, and reduces the possible deviation or jitter of the equipment during operation. Stable operation not only improves production efficiency, but also effectively extends the service life of the rolling mill equipment.

Reduce equipment wear

High-quality guide materials can reduce friction with rolling mill components, reduce the heat generated by friction, and thus reduce equipment wear. In this way, the maintenance cycle of the rolling mill has also been significantly extended, thereby reducing production costs.

Enhance production accuracy

Through the precise design and installation of rolling mill guides, the precise docking of various components during the rolling process can be ensured. This is crucial to improving the yield and quality of steel products. Especially in areas with high precision rolling requirements, the quality of the rolling mill guide equipments directly affects the appearance and strength of the final product.

Improve operational safety

The rolling mill guide is not only a mechanical support structure, it also plays a role in safety protection. During high-intensity rolling processes, the rolling mill guide can effectively prevent the equipment from accidentally shifting or tilting, avoiding potential safety risks to equipment and personnel.

Application scenarios of rolling mill guides

Rolling mill guides are widely used in the steel and metallurgical industry, especially in various rolling processes such as hot rolling, cold rolling, and finishing rolling. They are indispensable infrastructure. Whether it is the production line of a steel plant or a metal processing plant such as aluminum alloy and copper alloy, the rolling mill guide can ensure the smooth operation of the equipment while improving the overall efficiency of the production line.

Choose the right rolling mill guide

When choosing rolling mill guides, enterprises should consider the following aspects:

Material selection

The material of the rolling mill guide should have sufficient strength and wear resistance. Common rolling mill guide materials include high-strength steel, alloy steel, etc. These materials can withstand long-term high-load use, and corrosion resistance is also particularly important.

Precision and stability of rolling mill guides

The design accuracy of the rolling mill guide directly affects the operating stability of the rolling mill equipment. High-precision rolling mill guide can reduce equipment deviations and ensure the smoothness of the production process. When purchasing, enterprises should choose high precision and strong stability rolling mill guides.

High temperature resistance

During the hot rolling process of the rolling mill, the equipment will generate a lot of high temperature. In order to ensure the normal operation of the rolling mill guides, it is very important to choose rolling mill guides that are resistant to high temperature and thermal fatigue. By using high-temperature resistant materials, enterprises can ensure the stability of the rolling mill guides in high temperature environments.

Maintenance and maintenance of rolling mill guides

Although high-quality rolling mill guides have a long service life, regular maintenance and maintenance cannot be ignored. Regularly check whether the rolling mill guides are worn or cracked, and replace damaged parts in time to extend the service life of the entire production line.

Summary

As a key component in steel production, rolling mill guides bear important support and guidance functions. Their stability, durability and precision directly affect the efficiency and quality of the entire production process. Therefore, when purchasing rolling mill guides, enterprises must ensure the high quality of materials and excellent design, and perform regular maintenance. Only in this way can the rolling mill equipment be ensured to operate efficiently, stably and safely, improve production efficiency and reduce maintenance costs.