Roller Entry Guide in the Steel Industry Application

Release time: 2025-08-25

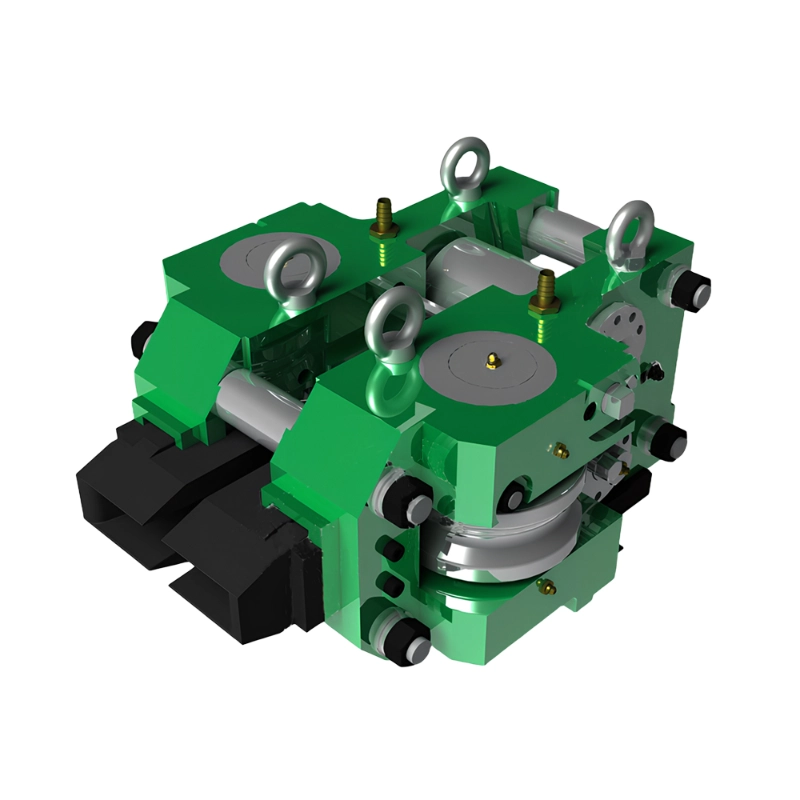

In the steel industry, roller entry guide, as key precision guide components, play a vital role. Whether in hot rolling, cold rolling, or other steel processing processes, roller entry guide play a vital role. They effectively guide and maintain the stability of steel, ensuring machining accuracy, improving production efficiency, and reducing equipment wear. With the modern steel industry’s ever-increasing demands for efficiency and precision, the use of roller entry guide has become a crucial tool for improving the quality and profitability of steel production.

Working Principle and Function of Roller Entry Guide

The primary function of roller entry guide is to precisely guide steel sections with complex cross-sections (such as H-beams, angles, and channels), ensuring stable operation during machining and minimizing deviation and deformation. In the steel industry, roller entry guide precisely position and guide steel, preventing unnecessary deviation and impact, thereby ensuring stable machining under high-temperature, high-speed conditions.

Furthermore, roller entry guide possess strong compressive and wear resistance, enabling them to maintain stability and efficiency under high loads and harsh environments. In this way, it can not only improve production efficiency, but also extend the service life of mechanical equipment.

Application of roller entry guide in steel production

Application in hot rolling process

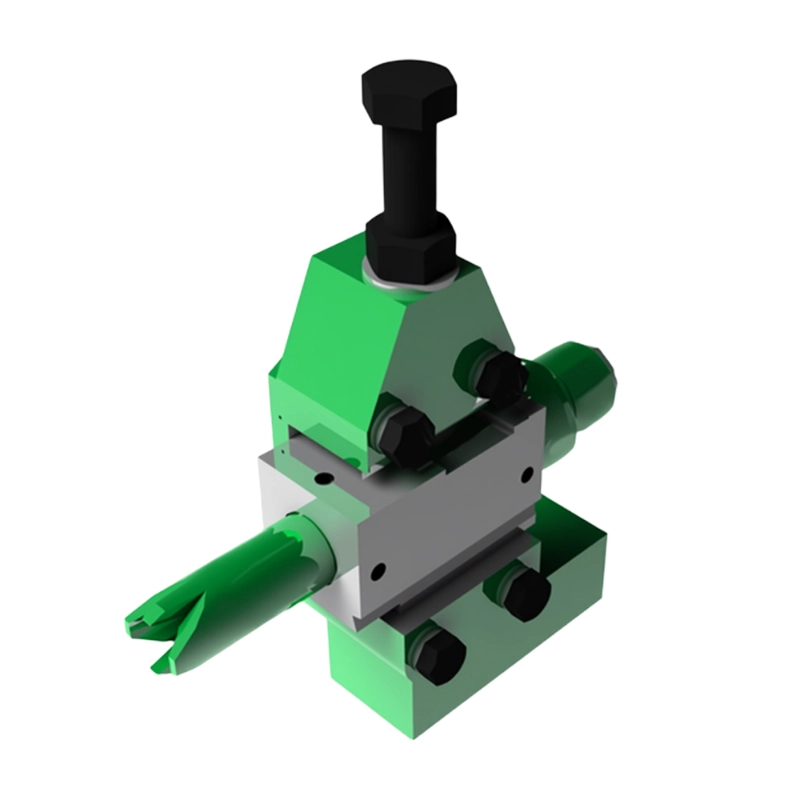

During the hot rolling process, steel materials are treated with high temperature and enter the rolling mill for plastic deformation. Since steel is easily deformed at high temperatures, it is crucial to maintain the shape and dimensional accuracy of the steel. High-performance roller entry guide ensure that the steel can maintain a stable direction when passing through the rollers through precise guidance, avoiding deformation or dimensional deviation of the steel caused by inaccurate guidance.

In high-temperature environments, the high-temperature resistance of roller entry guide is crucial. It needs to have excellent thermal stability to ensure that it will not lose its function due to thermal expansion or corrosion under long-term high-temperature operation.

Application in cold rolling process

The cold rolling process usually processes steel at room temperature or low temperature conditions, and the accuracy requirements in this process are more stringent. During the cold rolling process, roller entry guides ensure the surface finish and dimensional tolerance of the steel by accurately guiding the movement trajectory of the steel. Especially when rolling thin steel plates or precision steel sections, roller entry guide can effectively control the shape of the steel, avoid surface defects and internal stress problems, and improve the product yield.

Steel transportation and handling

Roller entry guides not only play a guiding role in the rolling process, but are also widely used in the steel transportation and handling system. In the production line of a steel plant, a large amount of steel needs to be transported through the transportation system. Roller entry guides can ensure the stability of the steel in this process and avoid deformation and collision of the steel during transportation, thereby improving transportation efficiency and safety.

Advantages of Roller Entry Guide

High load capacity and durability

Roller entry guides are usually made of high-strength steel or alloy steel. After rigorous heat treatment and surface treatment processes, they have excellent pressure resistance and wear resistance. In the steel industry, equipment needs to withstand high-intensity, high-speed impact and friction. Therefore, the durability of roller entry guide directly affects the stability of production.

Improve production efficiency

Through precise guidance, roller entry guide can effectively reduce the deviation of steel during processing and avoid reprocessing due to inaccurate dimensions. This can greatly improve production efficiency, reduce the production of defective products, and reduce the frequency of equipment maintenance, ensuring the efficient operation of the production line.

Reduce maintenance costs

In the steel industry, equipment maintenance costs usually account for a large part of production costs. The durability and high precision of roller entry guide can reduce equipment wear and extend the service life of equipment, thereby reducing the number of downtimes and maintenance costs. This is undoubtedly an effective way for steel mills to reduce production costs.

Conclusion

In short, high-precision roller entry guides, as an indispensable and important component in the steel industry, have become a key tool for improving production accuracy and efficiency. It not only ensures the stable operation of steel under high load and high temperature environments, but also reduces equipment wear and reduces maintenance costs. In steel production, roller entry guide will continue to play an important role and develop in a more intelligent, efficient and environmentally friendly direction.