| Model NO. | As Per Requirement Drawing |

| Condition | New |

| Material | Carbide Steel |

| Payment Terms | T/T, LC, CAD etc. |

| Incoterm | FOB/CIF/DDU/DDP |

| Transport Package | Wooden Case |

| Transportation | Ocean |

| Port | SHANGHAI |

| Specification | Customized |

| Certification | ISO 9001/ISO 45001/CE/RoHS/REACH/CBAM |

| Trademark | SN |

| HS Code | 8455900000 |

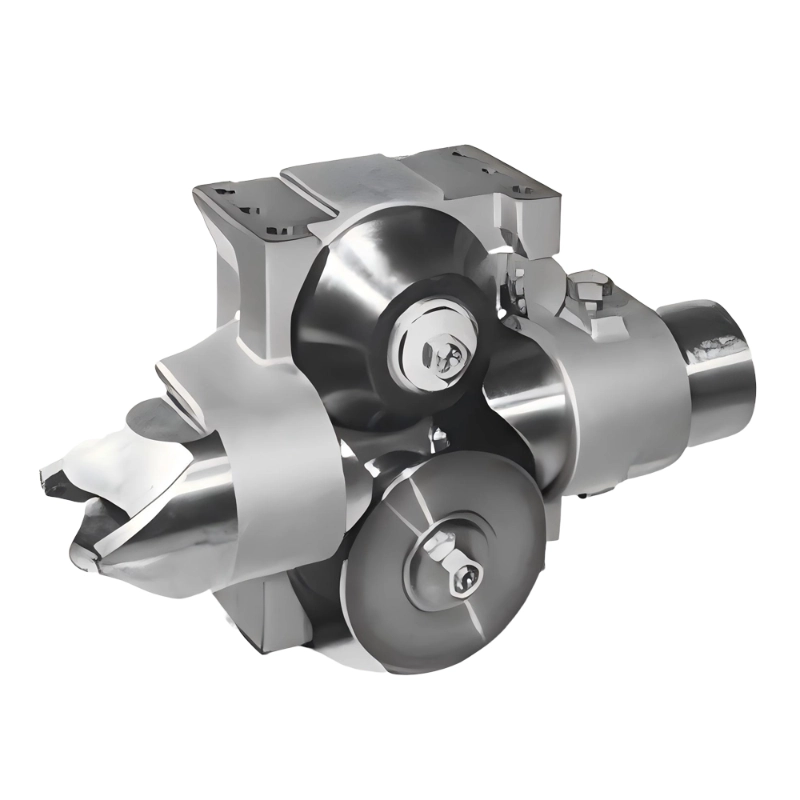

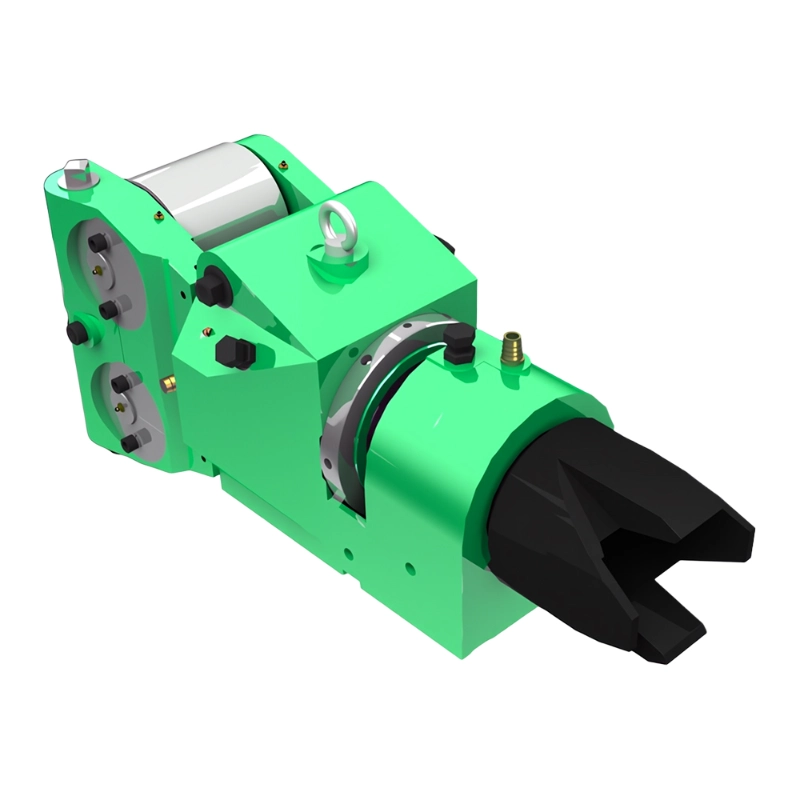

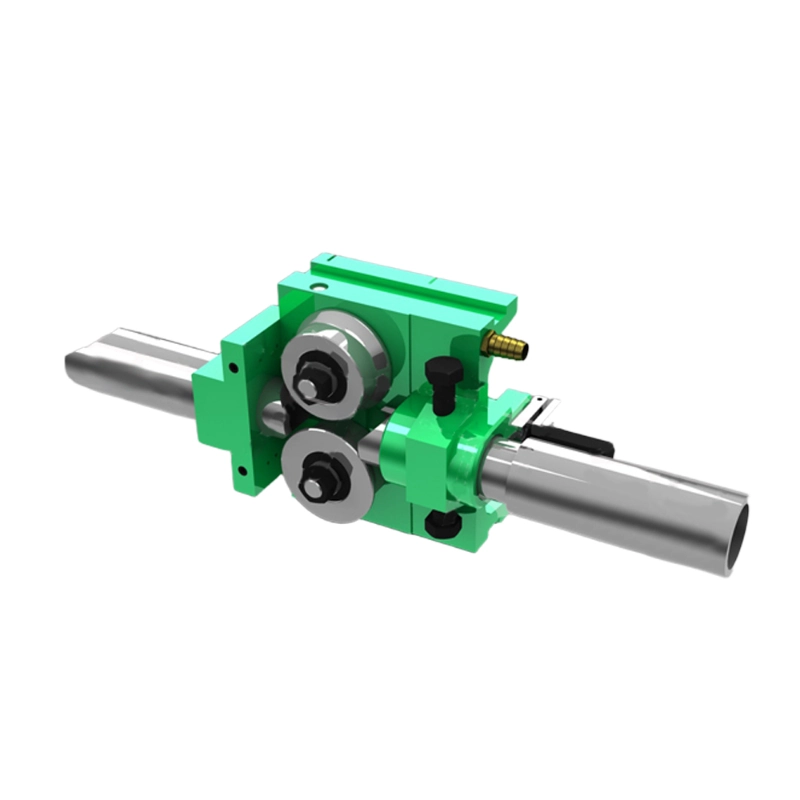

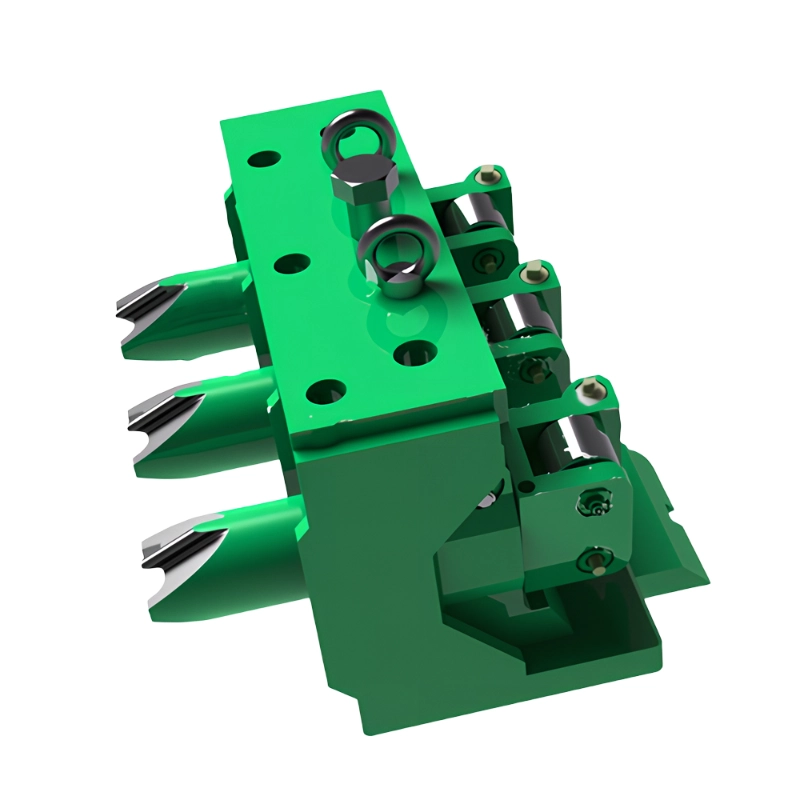

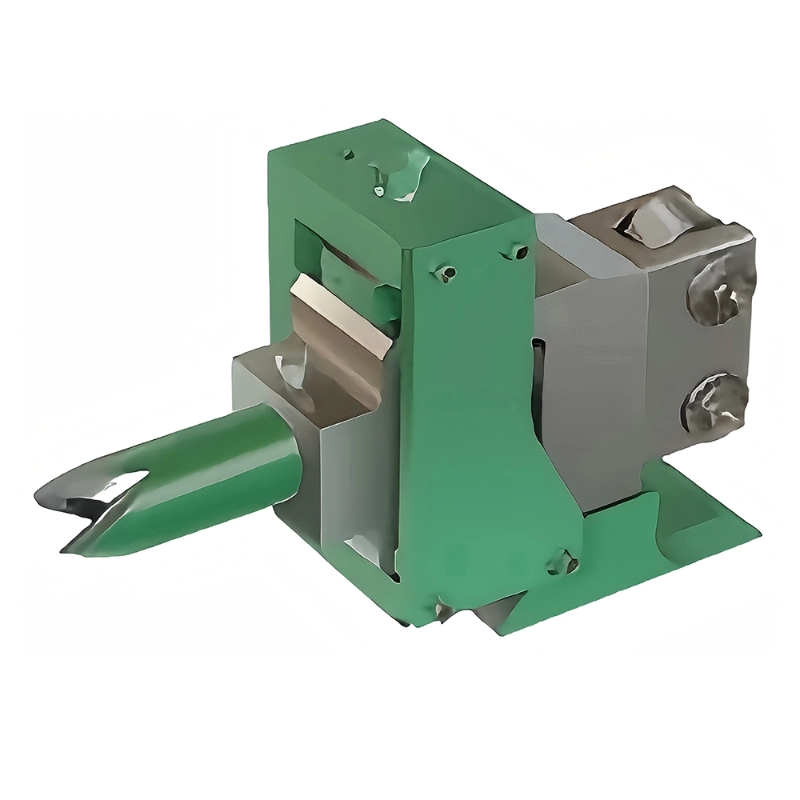

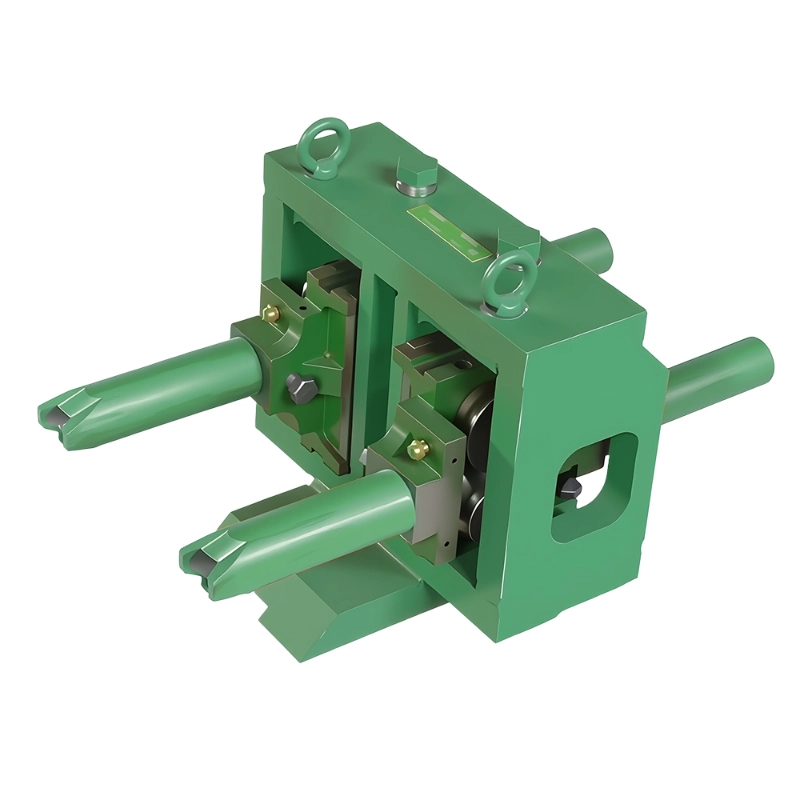

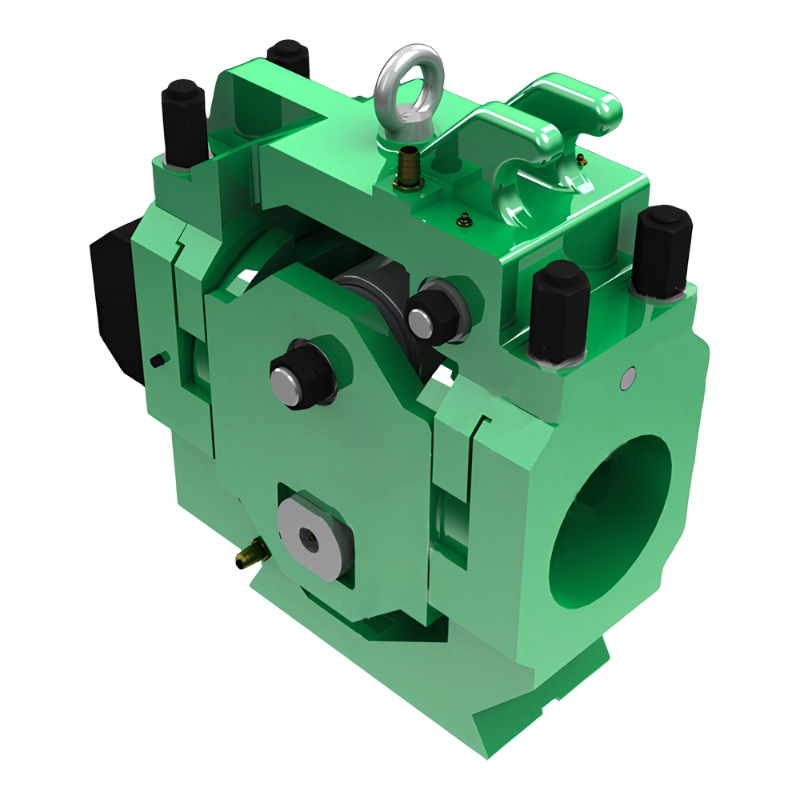

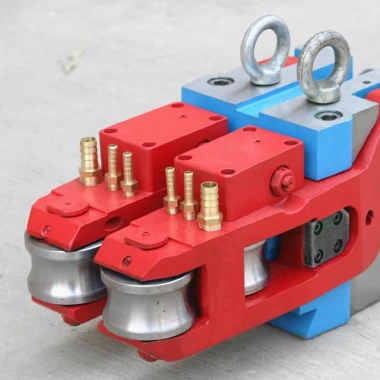

Precision Wire Rod Roller Twister Guides – Reduced Scrap

parameter

- Product Introduction

- Video

- Download

Features:

1. Enhanced Roll Stability:

Designed with robust materials (e.g., high-chrome alloy or tungsten carbide), it withstands extreme thermal/mechanical stresses, reducing wear and prolonging service life.

2. Optimized Twist Mechanism:

Engineered for smooth, controlled twisting of workpieces, preventing surface scratches and ensuring uniform deformation in high-speed rolling.

Shennuo Metallurgical Machinery Co., Ltd.’s high-performance twist guides are core components for optimizing rolling mill efficiency and precision. By offering stable and accurate twisting guidance, they ensure dimensional tolerances and surface finish of the final products. This effectively reduces overall equipment wear , thereby achieving cost reduction and efficiency improvement.Key Features include:

High-Precision Guidance and Stable Twisting: It is essential to prevent any shaking, bending, or deviation from the rolling line during the twisting process.

Excellent Wear Resistance and Service Life: Operating in high-temperature and high-speed conditions,the twist guides are exposed to intense friction and impact. Therefore, they are usually made from high-strength, heat-resistant, and wear-resistant alloy steel (such as H13 steel) and undergo special heat treatment processes (like nitriding) to extend their service life.

Precise Groove Design: The groove profile of the twist guides is meticulously calculated and designed to highly match the size and cross-sectional shape of the workpiece. This ensures the workpiece twists smoothly, which prevents surface scratches.

Effective Cooling System: Continuous water cooling prevents the twist guides from softening, deforming, or wearing prematurely due to overheating.

We are rolling mills guide and guards manufacturer in China, which suit the final products are round steel, deformed steel and wire rod. There will be good cooperation chance If you

- Have the raw material of billet or steel scraps

- Want to build a steel factory

- Don’t know how to process or design the production line

- Want to add the production line

- Want to purchase the accessories

- Want to reduce the invest budgets since the high cost from European countries and long term RIO period

Service:

1) Providing professional proposal of suitable production line as per customers’ invest and capacity requirement

2) Providing turn-key service of designing, manufacturing, installation and commissioning for the whole production lines to meet customers requirement

3) Providing foundation layout and arrangement diagram for your plant

4) Providing technical support. We will send various technical staff to the site until the final products are meet to customers’ own request.

5) Good after-sales service will be provided. Our long-term technical service will be provided if you want to adjust the production line, develop new products or improve the equipment.

6) Quality warranty will be promised.

Please send us more informations about your project, we would like to give you proposal immediately after getting your details. Sincerely welcome you to come and visit our plant.

Related Products