Optimizing Rolling Mill Yield with High-Performance Entry & Exit Guides

Release time: 2026-02-06

In the high-pressure environment of modern steel rolling, the difference between a profitable shift and a costly shutdown often lies in the smallest components. While the rolling stands and motors get the glory, the Mill Guides (Entry and Exit) are the unsung heroes that dictate the quality of the final product. For procurement managers and mill engineers across the globe, sourcing guides is no longer about finding a generic casting; it is about finding a precision instrument capable of withstanding extreme thermal and mechanical stress.

The “Anti-Scratch” Imperative

The most frequent search query among quality control managers involves “surface defects.” A sub-par guide roller or a static guide with poor surface finish is the primary culprit for scratches and lap marks on wire rods and bars.

High-performance guides address this through advanced metallurgy. Leading manufacturers utilize special alloy steels for the guide body and high-hardness materials for the rollers. The goal is to ensure that the guide resists wear from the red-hot steel (often exceeding 1000°C) without transferring marks onto the product. If the guide wears down unevenly, the steel bar wanders, leading to dimensional inaccuracies.

Thermal Management and Bearing Life

In high-speed wire rod mills, the rollers within the guide box spin at incredibly high RPMs. The failure of a bearing inside a guide box is a catastrophic event—it causes the roller to seize, leading to an immediate “cobble” (a pile-up of hot steel).

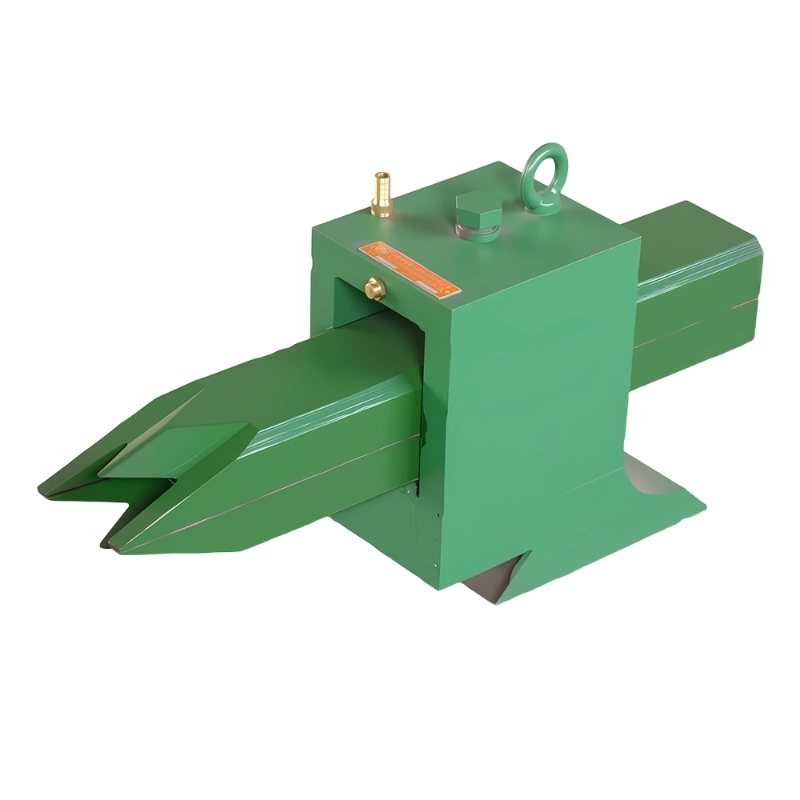

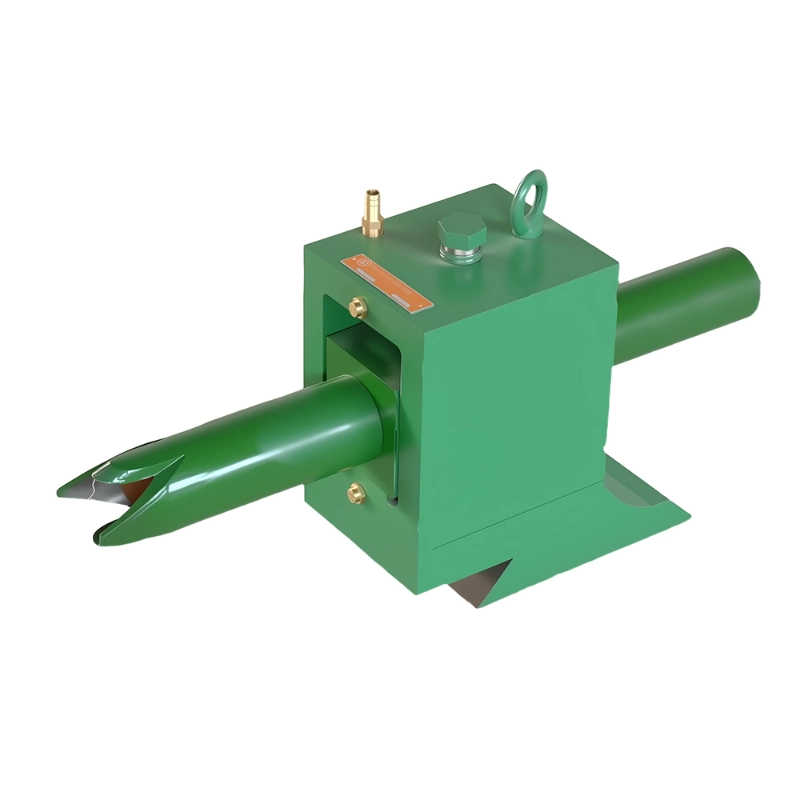

Premium guides feature precision-engineered cooling channels. These internal pathways are designed to direct water/air mist exactly onto the bearings and the roller interface. This efficient heat dissipation prevents the lubricant from breaking down and the bearings from seizing. When sourcing guides, the design of this cooling system is a critical technical parameter to verify.

Entry vs. Exit: Understanding the Dynamics

To the untrained eye, entry and exit guides look similar, but their functions—and stress points—differ:

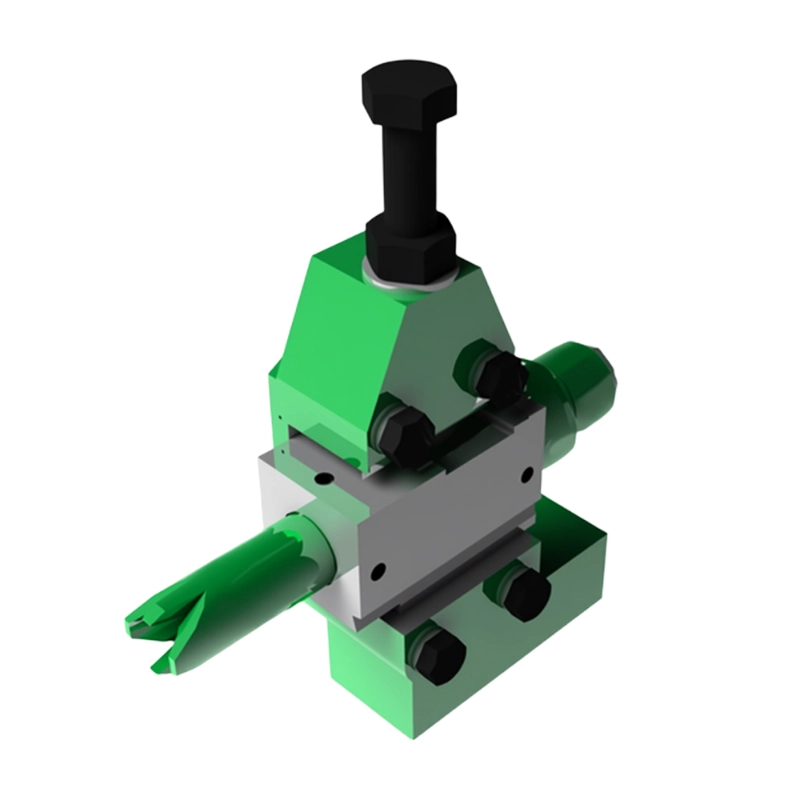

- Entry Guides: Must provide rigid stability to center the billet or bar perfectly into the roll pass. Any vibration here translates to a deformed product. The focus here is on structural rigidity.

- Exit Guides: Must “strip” the steel from the rolls cleanly and guide it to the next stand. They face intense impact and abrasion. The focus here is on wear resistance and impact toughness.

The Economics of Uptime

Cheap guides often require replacement every few shifts. A “High-Performance” guide, conversely, is an investment in uptime. By maintaining its dimensions longer, it reduces the frequency of mill stops for adjustments. Furthermore, by preventing cobbles, it saves tons of material from the scrap heap. When evaluating suppliers, look for those who specify machining tolerances and material hardness levels—these are the indicators of a product built for longevity.

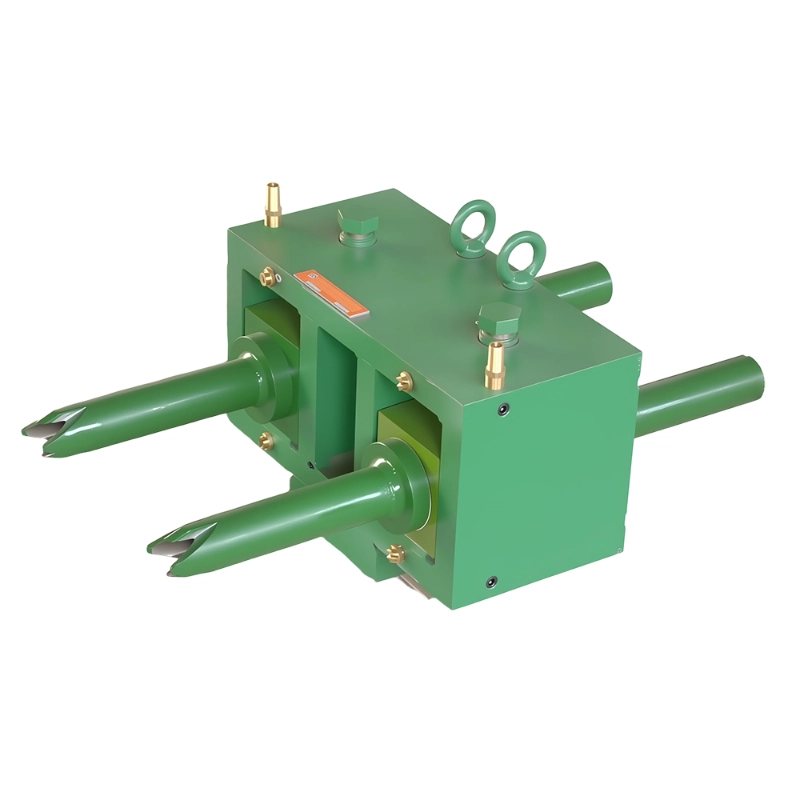

High-Performance Mill Guides

If your facility is looking to minimize downtime and improve the surface finish of your rolled products, Hefei Shennuo offers the High-Performance Entry and Exit Mill Guide.

Our guides are precision-machined from durable alloy steel, designed specifically to handle the rigors of modern high-speed rolling. With optimized cooling channels to protect bearings and wear-resistant rollers to prevent surface scratches, our guide boxes are engineered to boost your mill’s yield rate. We provide a robust solution that ensures the steel travels smoothly from the first stand to the finishing block.

FAQ

Q1: What is the primary cause of guide roller failure?

A: The most common cause is bearing failure due to overheating or contamination. Our high-performance guides feature enhanced cooling and sealing systems to extend bearing life significantly.

Q2: Can these guides be used for both slit rolling and conventional rolling?

A: Yes, but the specific design differs. We offer guides tailored for multi-slit rolling (which requires extreme precision to separate the bars) as well as conventional profiles.

Q3: How do your guides help prevent “cobbling”?

A: By using rigid materials and precise machining, our guides maintain a tight grip on the bar, preventing it from twisting or turning inside the pass, which is the leading cause of cobbles.

Q4: Do you support custom guide designs for non-standard profiles?

A: Absolutely. As a manufacturer, we can engineer entry and exit guides based on your specific roll pass design and mill speed parameters to ensure a perfect fit.