Pemandu Masuk dan Keluar Pabrik Penggilingan vs. Pemandu Rol Pabrik Penggilingan: Bagaimana Memilih Pemandu Masuk yang Tepat untuk Pabrik Penggilingan Anda?

Release time: 2026-01-12

Daftar isi

In the steel rolling industry, the debate between using entry and exit mill guides and rolling mill roller guides is long-standing. Both play a critical role in directing the workpiece into the roll pass, but selecting the wrong one can lead to surface defects, frequent downtime, and increased production costs.

Understanding the technical nuances between these two systems is essential for optimizing your mill’s performance. Here is a comprehensive guide to help you make the right choice.

The Case for Entry and Exit Mill Guides: Simplicity and Stability

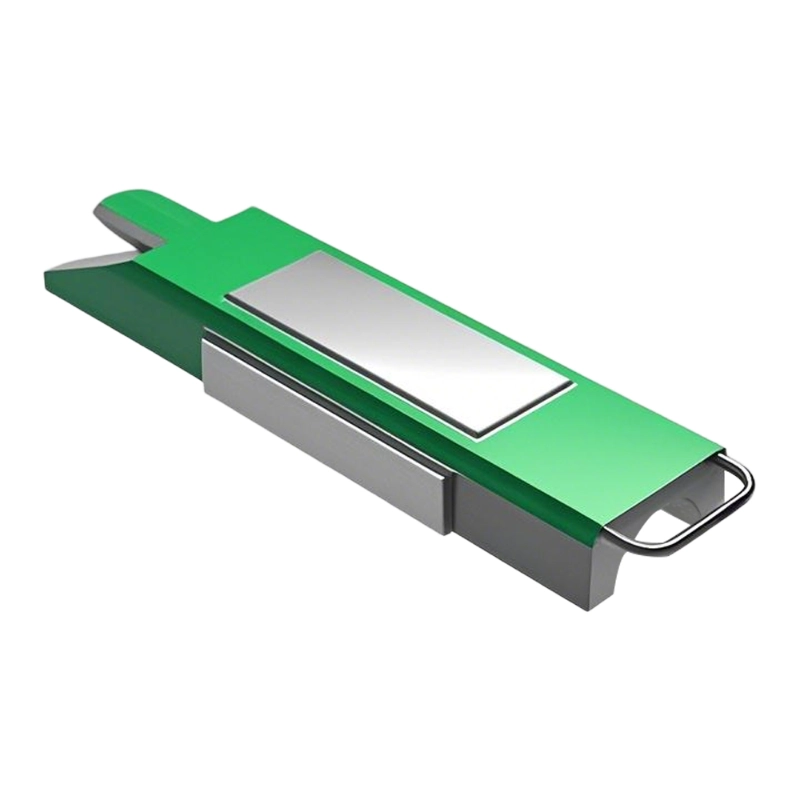

Entry and exit mill guides, often referred to as static guides, rely on a fixed surface to channel the steel. These are the preferred choice for many steel plants due to their robust construction and cost-effectiveness.

For mills handling complex shapes or specific metallurgical grades, a flexible entry and exit mill guide offers significant advantages. Unlike rigid systems, these guides can be adjusted or swapped quickly to accommodate different pass designs. Furthermore, in high-heat environments where bearings in roller guides might fail, a high-temperature resistant entry and exit mill guide proves its worth. These guides are often made from specialized wear-resistant alloys that maintain their structural integrity even under extreme thermal stress.

Best for:

- Heavy-duty sections and large profiles.

- Environments with extreme heat where roller bearings might seize.

- Lower-budget operations looking for high durability with minimal mechanical complexity.

The Case for Rolling Mill Roller Guides: High Speed and Low Friction

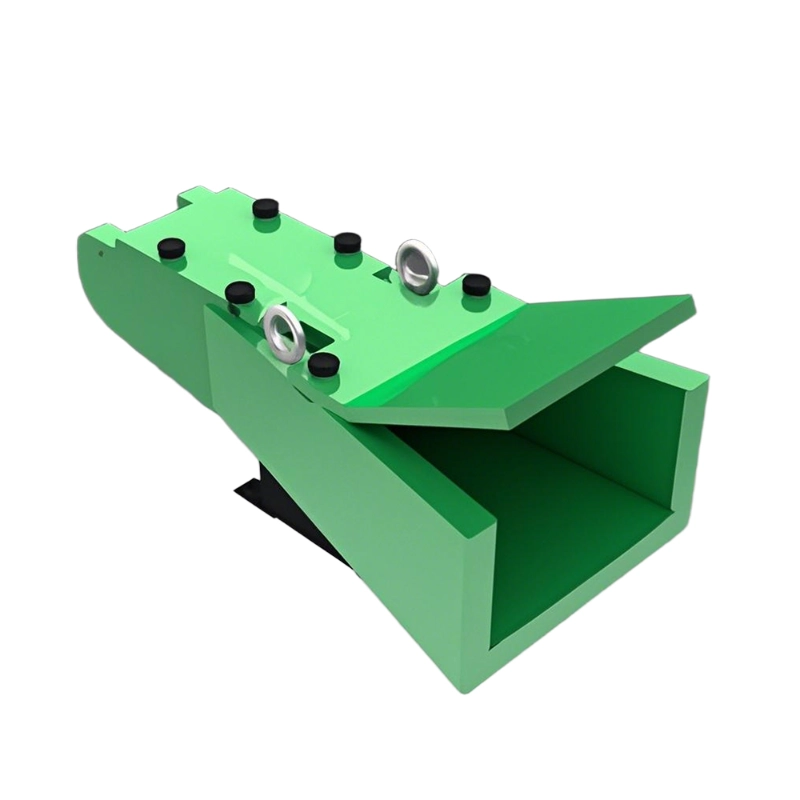

Rolling mill roller guides use rotating rollers to contact the workpiece. This design significantly reduces friction, which is vital for high-speed wire rod or bar mills where surface finish is a top priority.

For large-scale industrial applications, a heavy-duty rolling mill roller guide is often employed. These systems are engineered to handle the massive kinetic energy of fast-moving steel, reducing the risk of “pick-up” or material transfer from the guide to the product. However, rolling mill roller guide require a more sophisticated maintenance regime, including precision bearing lubrication and frequent roll inspections.

Best for:

- High-speed finishing blocks.

- Products sensitive to surface scratching.

- Mills with automated lubrication and high-precision maintenance capabilities.

Key Factors to Consider When Choosing

When deciding which guide system to install, consider the following three criteria:

Material and Wear Resistance

If your production involves abrasive materials, the contact surface of your guide will degrade quickly. Opting for a wear-resistant entry and exit mill guides can provide a longer service life in static setups, while rolling mill roller guide need high-quality carbide rollers to stay competitive in durability.

Production Speed

At lower speeds, the friction generated by a sliding-contact guide is negligible. However, as speeds increase, the heat generated by friction can damage both the guide and the steel. For ultra-high-speed lines, the rolling mill roller guide is almost always the winner.

Maintenance Capacity

Do you have a team capable of maintaining complex bearing systems? If not, a customized entry and exit mill guides is a smarter investment. It provides the precision you need without the mechanical headaches of rotating parts.

Conclusion: Making the Final Decision

There is no “one-size-fits-all” answer. The choice between a flexible entry and exit mill guides and a heavy-duty rolling mill roller guide depends entirely on your specific mill configuration, product type, and maintenance budget.

At Shennuo, we understand that every rolling mill has unique challenges. Whether you require a high-temperature resistant entry and exit mill guides for a rugged environment or a high-precision entry and exit mill guides for intricate profiles, our engineering team is ready to provide the perfect solution tailored to your needs.