How to Improve the Wear Resistance and Service Life of Roller Entry Guide

Release time: 2025-09-27

Table of Contents

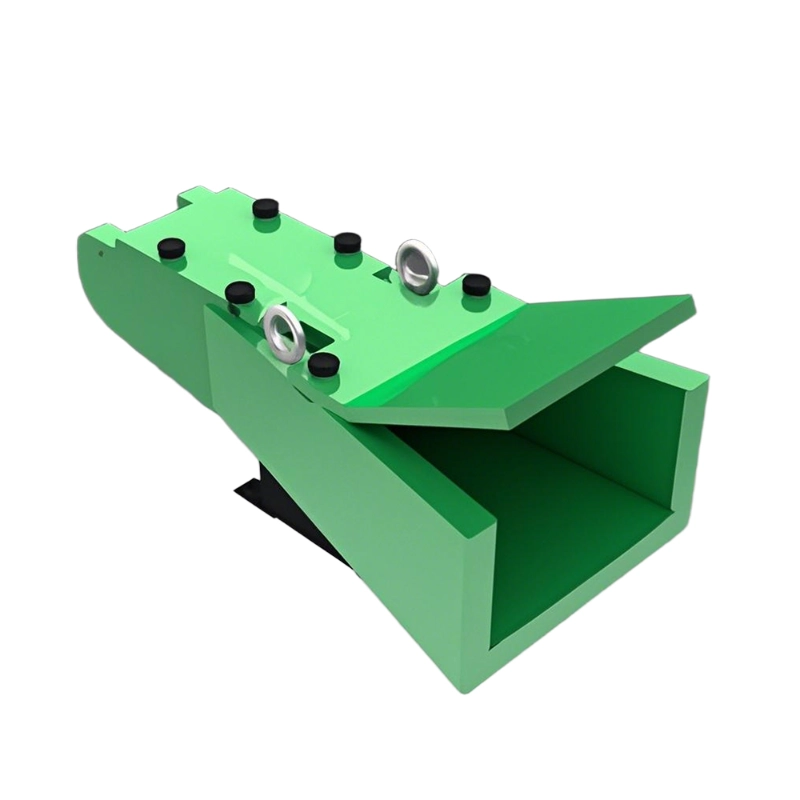

In modern machinery manufacturing and construction, roller entry guides serve as crucial load-bearing and guiding components, and their performance directly impacts the stability and service life of the equipment. With the increasing prevalence of industrial automation and high-precision equipment, improving the wear resistance of roller entry guide has become a core concern for many companies. This article will provide a detailed analysis of how to extend the service life of roller entry guides from four perspectives: material selection, surface treatment, design optimization, and maintenance.

Material Selection: The Foundation of Wear Resistance

The wear resistance of roller entry guides depends primarily on the material itself. High-strength alloy steels and wear-resistant composite materials are currently common choices. For example, alloying low-carbon steel or high-strength steel with added elements such as molybdenum and chromium can significantly improve the guide’s hardness and wear resistance. Furthermore, for specific environments, such as high-temperature or highly corrosive conditions, corrosion-resistant roller entry guides or materials with surface coatings can be selected to ensure long-term stable operation.

Surface Treatment: The Key to Extending Service Life

In addition to the material itself, surface treatment technology plays a decisive role in the wear resistance of roller entry guides. Common surface treatment methods include nitriding, carburizing, and hard coating spraying. These processes create a hardened layer on the guide surface, effectively reducing friction and wear, and preventing surface spalling and fatigue cracking. Furthermore, improved surface finish helps lower the coefficient of friction and improve equipment efficiency.

Design Optimization – A Prerequisite for Reducing Wear

Rational design is a key measure for extending the service life of roller entry guides. By optimizing the guide’s cross-sectional shape, guide surface contact area, and support structure, loads can be evenly distributed, localized stress concentrations can be reduced, and wear can be minimized. Furthermore, in high-load or high-frequency usage scenarios, the introduction of composite roller entry guides or adjustable clearance designs can effectively extend service life.

Maintenance – Ensuring Long-Term Stable Operation

Even with high-quality materials and advanced processes, lack of proper maintenance can shorten the life of roller entry guides. Regular inspection of guide wear, timely addition of lubricants, and removal of foreign matter are essential measures to maintain stable guide operation. Furthermore, establishing a service life monitoring and regular replacement system for roller entry guides in mechanical equipment can prevent equipment failures and production downtime caused by wear.

Conclusion

With the development of high-end equipment and intelligent manufacturing, demand for high-strength roller entry guides continues to grow in fields such as machinery, construction, and aerospace. By selecting high-performance materials, applying advanced surface treatment technologies, optimizing design solutions, and implementing scientific maintenance, companies can not only enhance the wear resistance of roller entry guides but also significantly extend their service life, thereby improving overall equipment efficiency. Focusing on optimizing the performance of roller entry guides is not only a requirement for technological upgrading but also a crucial factor in reducing costs and increasing efficiency.