| Model NO. | As Per Requirement Drawing |

| Condition | New |

| Material | Carbide Steel |

| Payment Terms | T/T, LC, CAD etc. |

| Incoterm | FOB/CIF/DDU/DDP |

| Transport Package | Wooden Case |

| Transportation | Ocean |

| Port | SHANGHAI |

| Specification | Customized |

| Certification | ISO 9001/ISO 45001/CE/RoHS/REACH/CBAM |

| Trademark | SN |

| HS Code | 8455900000 |

High-Performance OEM Mill Guides – Competitive Pricing

parameter

- Product Introduction

- Video

- Download

Features:

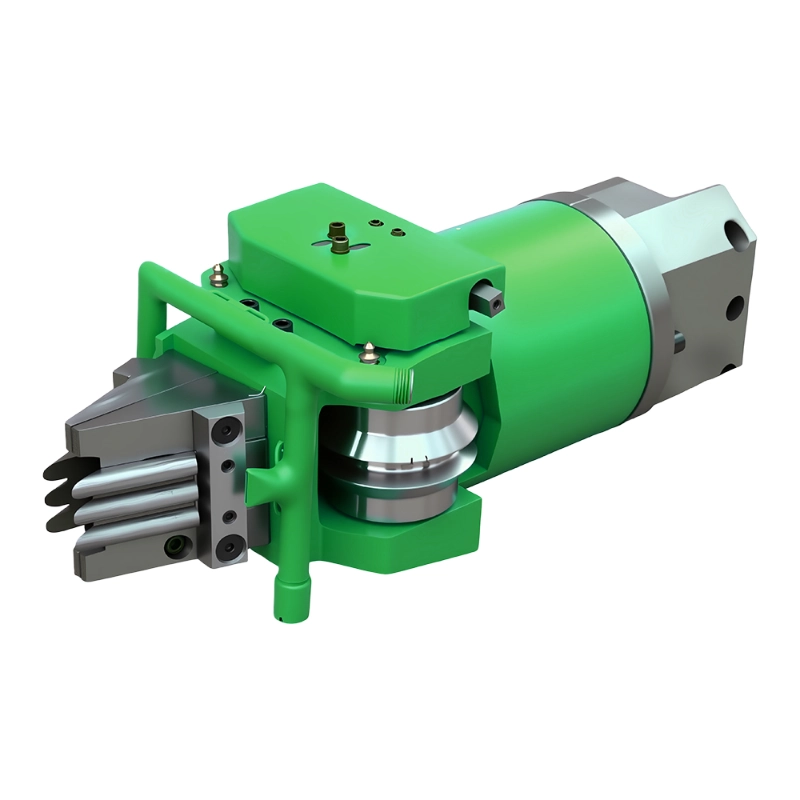

High Wear Resistance – Made from premium alloy materials (e.g., H13 steel, tungsten carbide coatings) to withstand extreme rolling forces and abrasive wear.

Optimized Cooling & Lubrication – Integrated cooling channels and lubrication systems enhance durability and reduce thermal stress

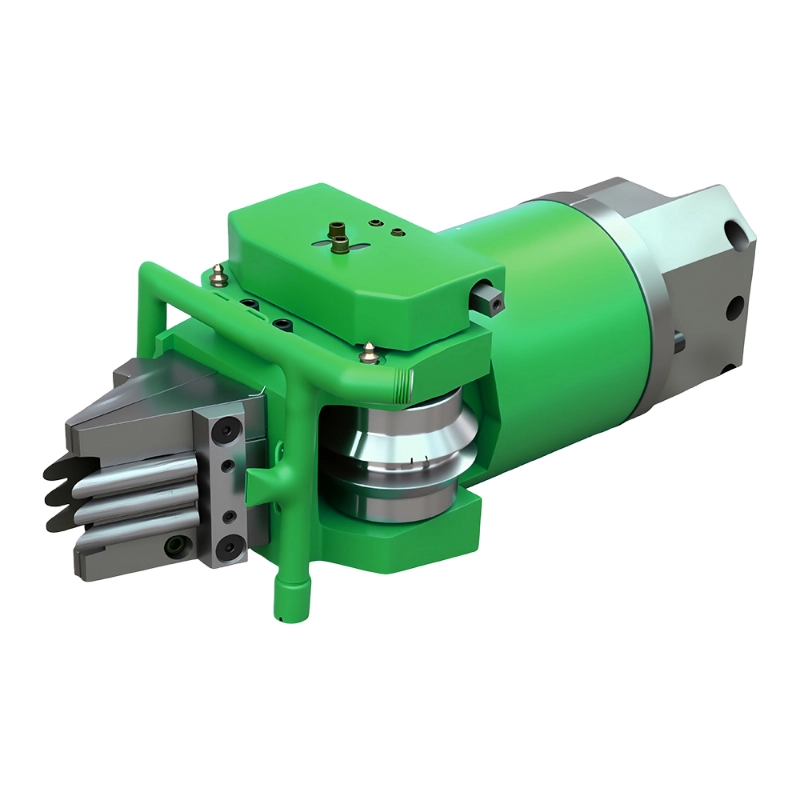

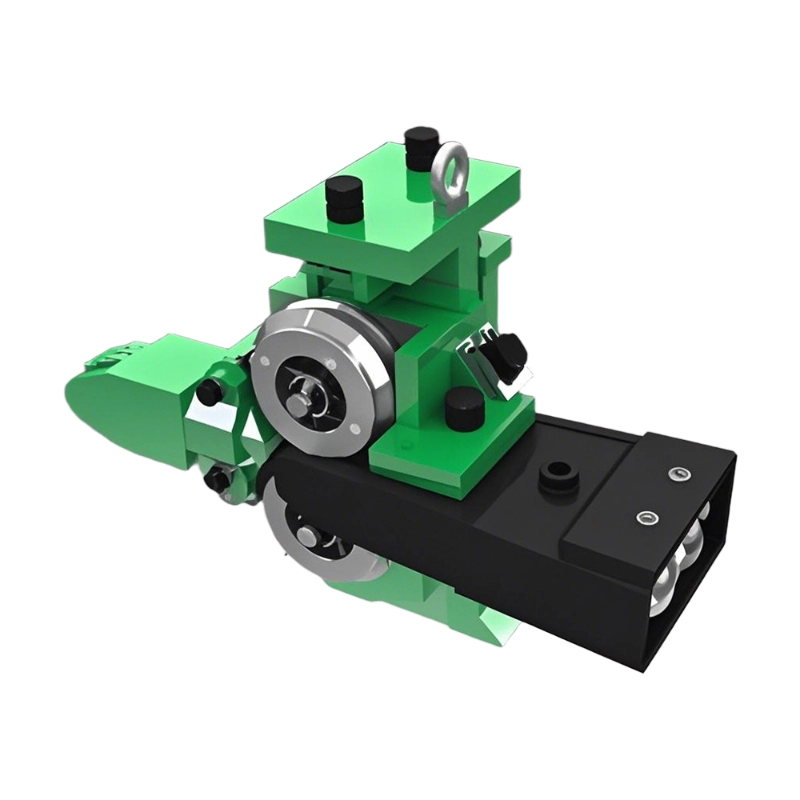

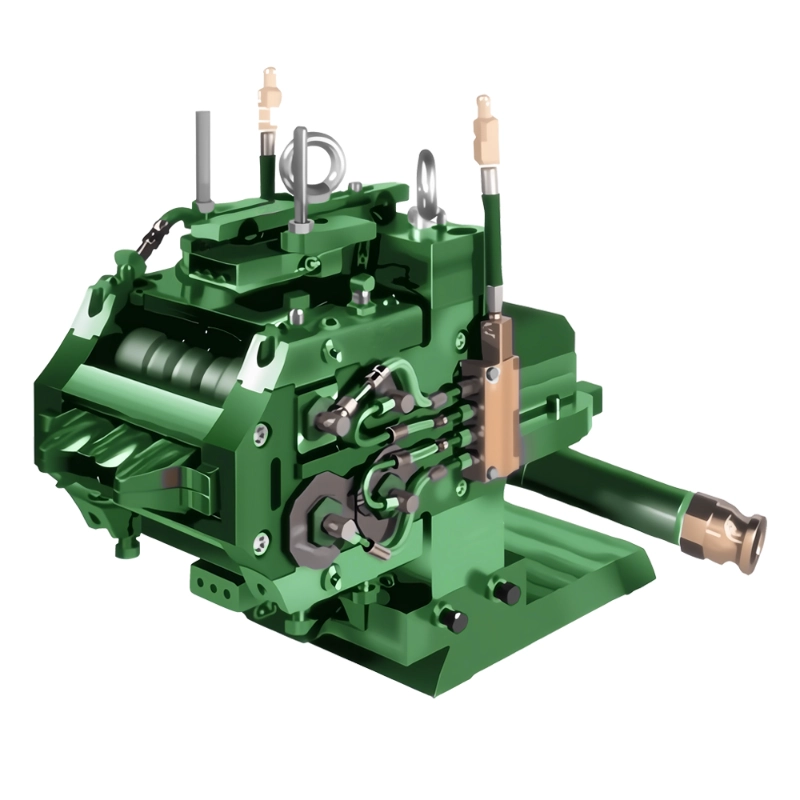

- Shennuo Metallurgical Machinery Co., Ltd. offers a range of high-precision sliding guides designed to enhance the efficiency and precision of rolling mill operations. These sliding guides are engineered to provide smooth and accurate guidance for rolling materials, ensuring consistent product quality and reduced wear on equipment. Key features include:

- Advanced Cooling Systems: Integrated water cooling systems help maintain optimal operating temperatures, enhancing guide performance and longevity.

- High Precision and Stability: Manufactured with advanced machining techniques, the sliding guides ensure precise alignment and stability during the rolling process.

- Durability and Longevity: Made from high-quality materials and subjected to rigorous quality control, these guides offer extended service life and reduced maintenance costs.

- Customizable Solutions: Available in various sizes and configurations to meet specific customer requirements, ensuring optimal performance in different rolling mill setups.

We are rolling mills guide and guards manufacturer in China, which suit the final products are round steel, deformed steel and wire rod. There will be good cooperation chance If you

- Have the raw material of billet or steel scraps

- Want to build a steel factory

- Don’t know how to process or design the production line

- Want to add the production line

- Want to purchase the accessories

- Want to reduce the invest budgets since the high cost from European countries and long term RIO period

Service:

1) Providing professional proposal of suitable production line as per customers’ invest and capacity requirement

2) Providing turn-key service of designing, manufacturing, installation and commissioning for the whole production lines to meet customers requirement

3) Providing foundation layout and arrangement diagram for your plant

4) Providing technical support. We will send various technical staff to the site until the final products are meet to customers’ own request.

5) Good after-sales service will be provided. Our long-term technical service will be provided if you want to adjust the production line, develop new products or improve the equipment.

6) Quality warranty will be promised.

Please send us more informations about your project, we would like to give you proposal immediately after getting your details. Sincerely welcome you to come and visit our plant.

Related Products